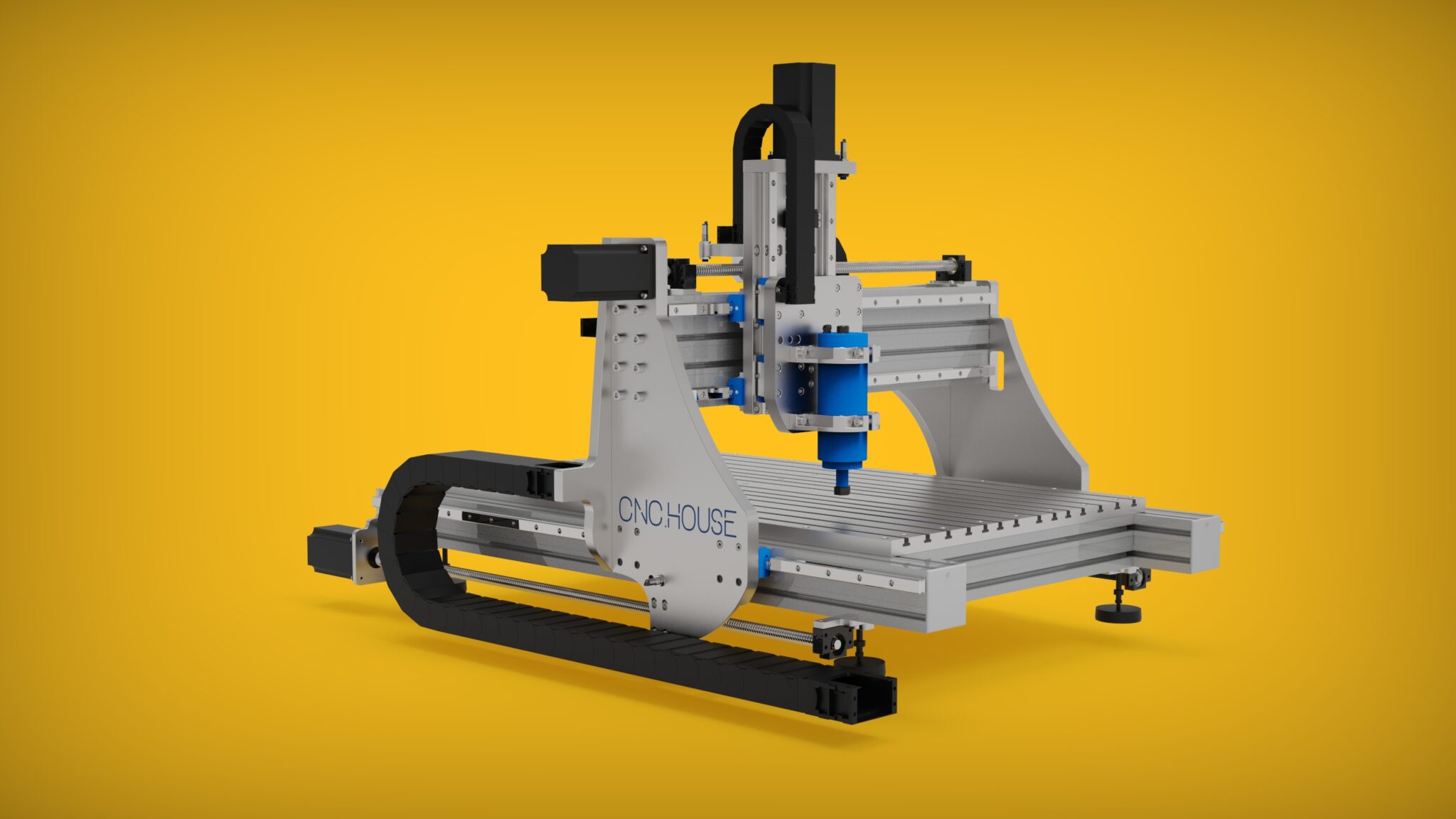

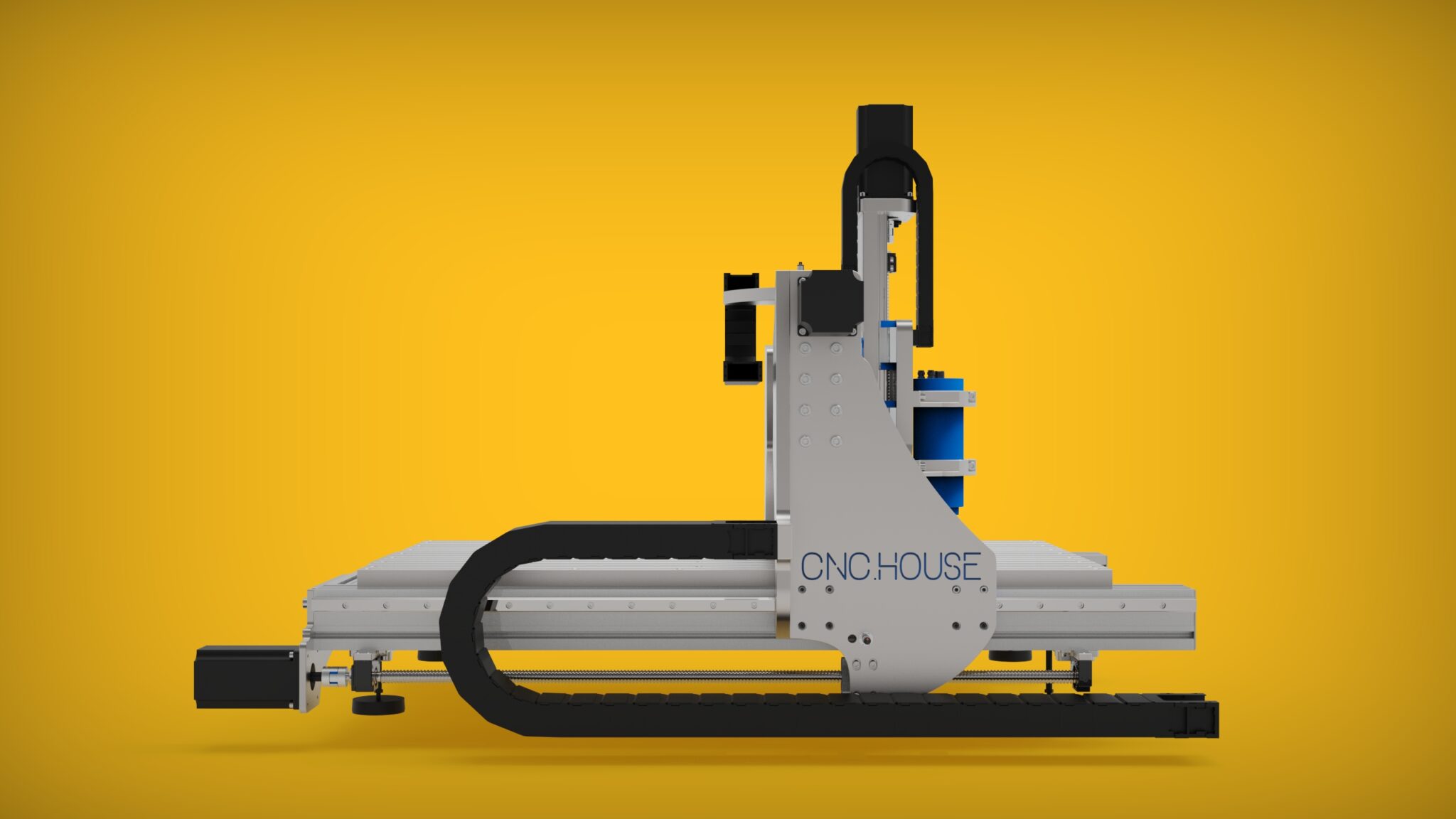

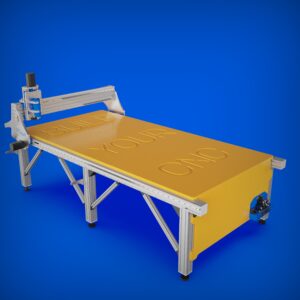

Pro Line CNC Kit with Closed Loop Stepper Motors and Ethernet Motion Controller

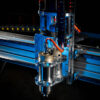

A remarkable leap in CNC machining, our Pro Line CNC Kit comes fully assembled, combining both mechanical and electrical components to provide an immediate, hassle-free machining experience.

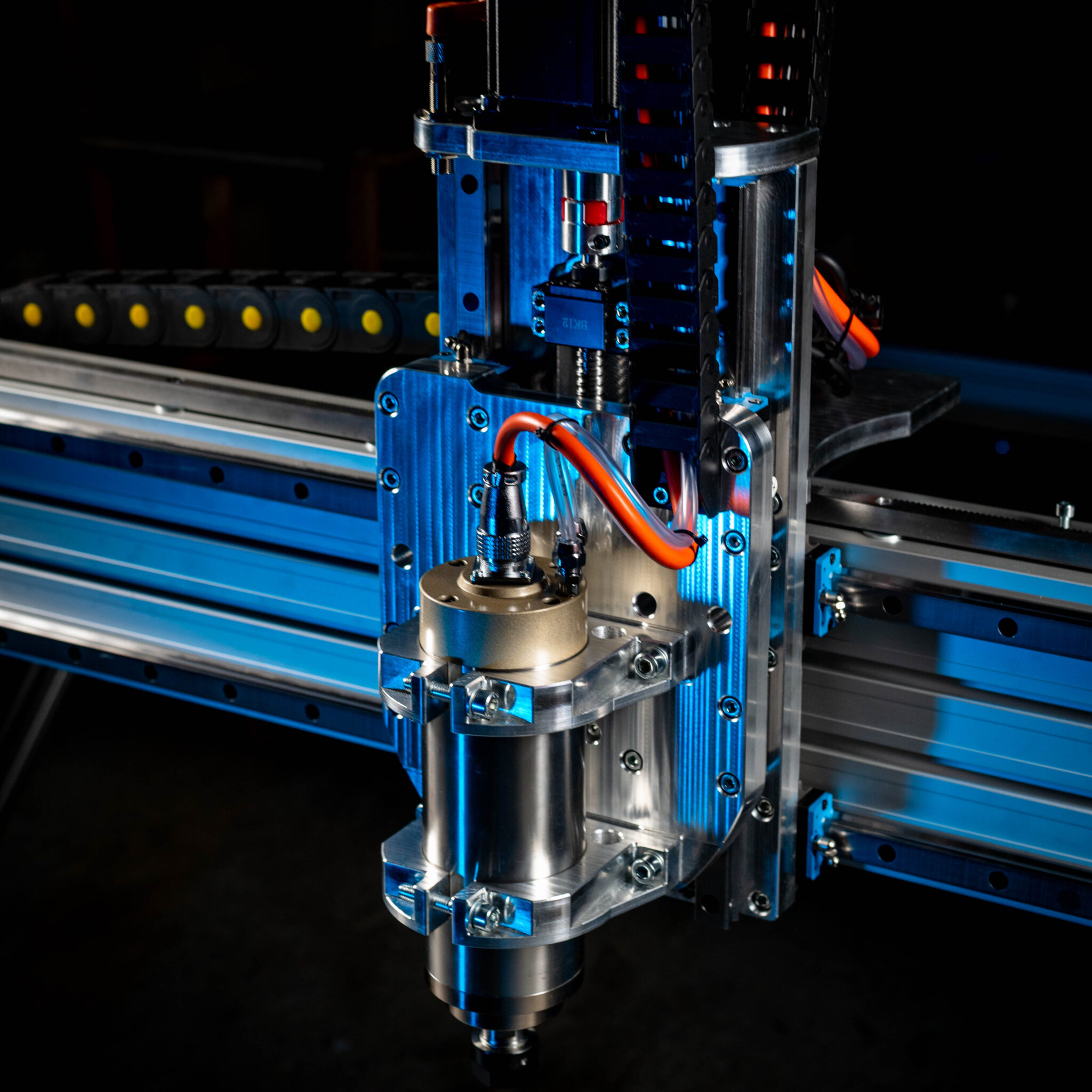

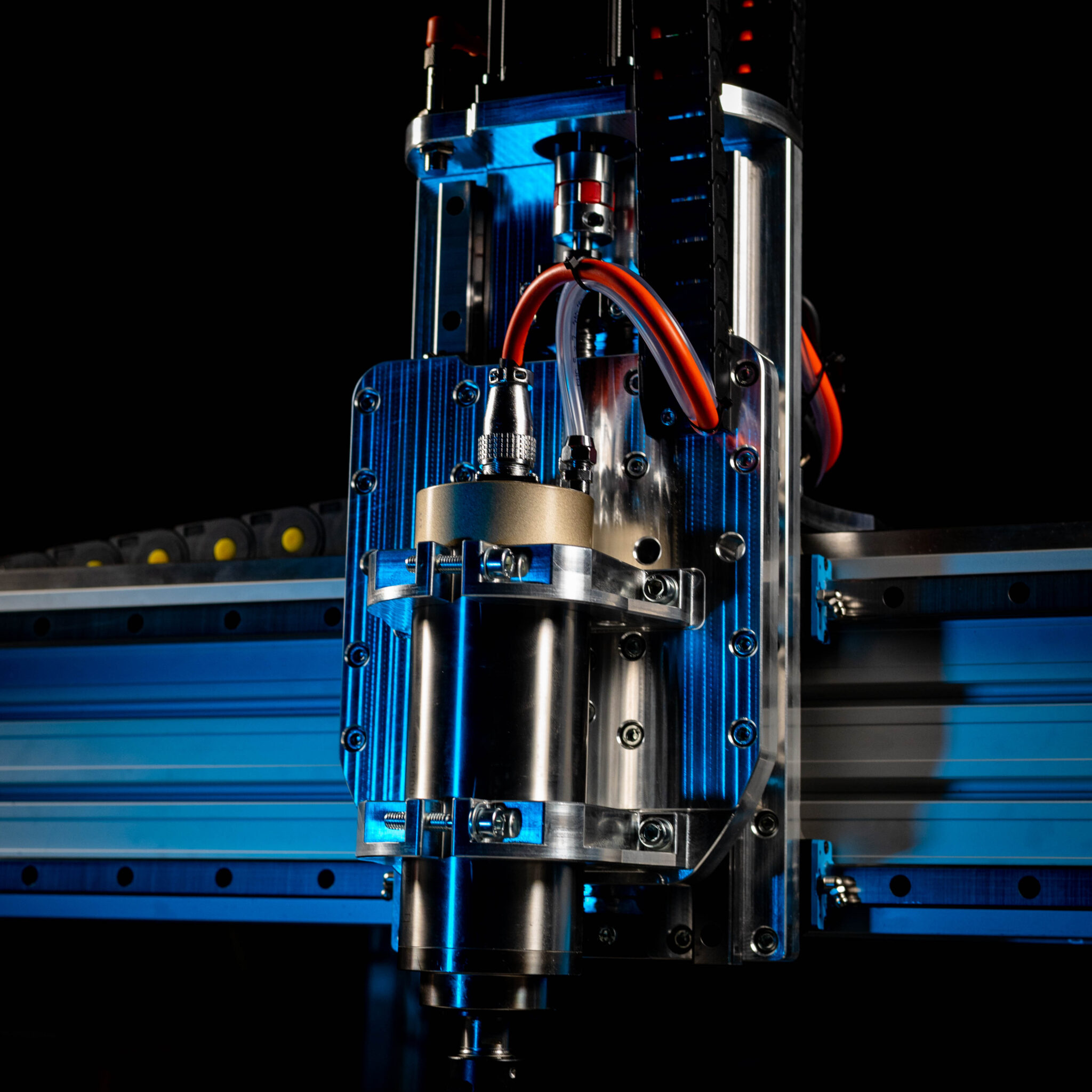

Spindle:

The Pro Line kit offers an array of robust spindle motors.

You can choose from a

- 2.2 kW Water-cooled spindle motor,

- 2.2 kW Air-cooled SPINOGY.DE X22 Series motor,

- 3.0 kW Water-cooled spindle motor,

- 3.5 kW Water-cooled spindle motor. Each of these motors can reach up to 24000rpm, ensuring precision and stability in your machining processes. A compatible Inverter VFD is included with each motor for efficient power conversion and control.

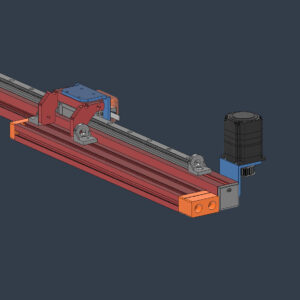

Linear Rails and Blocks:

Our kit employs original TBI Motion linear rails and carriages of size 20, offering smooth and precise linear motion during operations. These high-quality components assure longevity and optimal performance.

X and Y Axis Ball Screws and Nuts:

The Pro Line kit features meticulously engineered size 20 ball screws and nuts for the X and Y axes. These components provide low friction movement and extraordinary positioning accuracy, with included supports and coupling spider ensuring a secure connection.

Stepper Motors:

This kit exclusively uses high-torque NEMA 34 Closed Loop Stepper Motors with HBS86H 8A Hybrid Drivers. These motors deliver superior control over motion and positioning, an essential attribute for precision machining.

Frame and Construction:

The Pro Line model stands out for its robust construction. Utilizing high-quality Italian aluminum profiles and featuring main plates with a thickness of 25mm and additional 15mm plates, this machine is designed to withstand aggressive machining modes with minimal deformation.

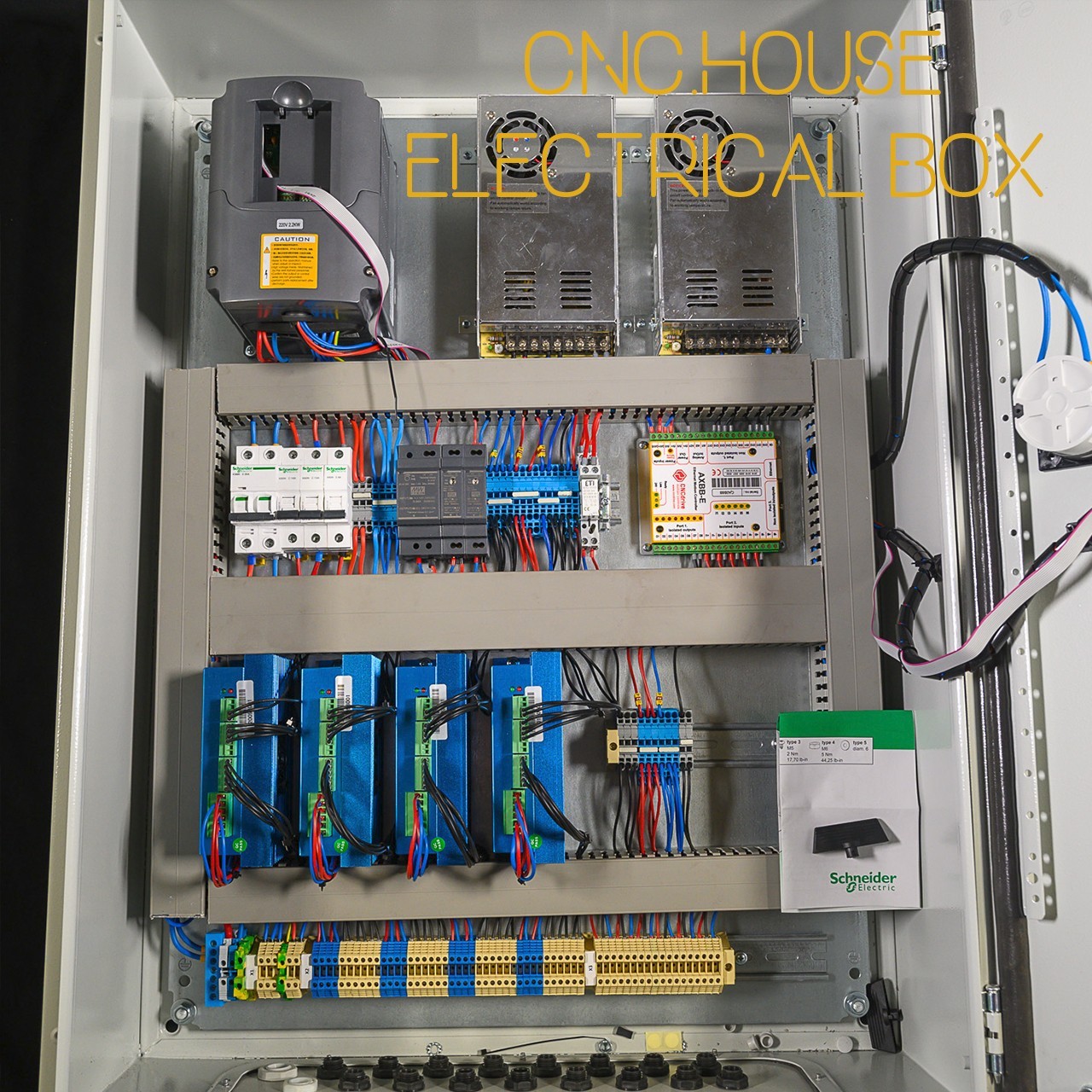

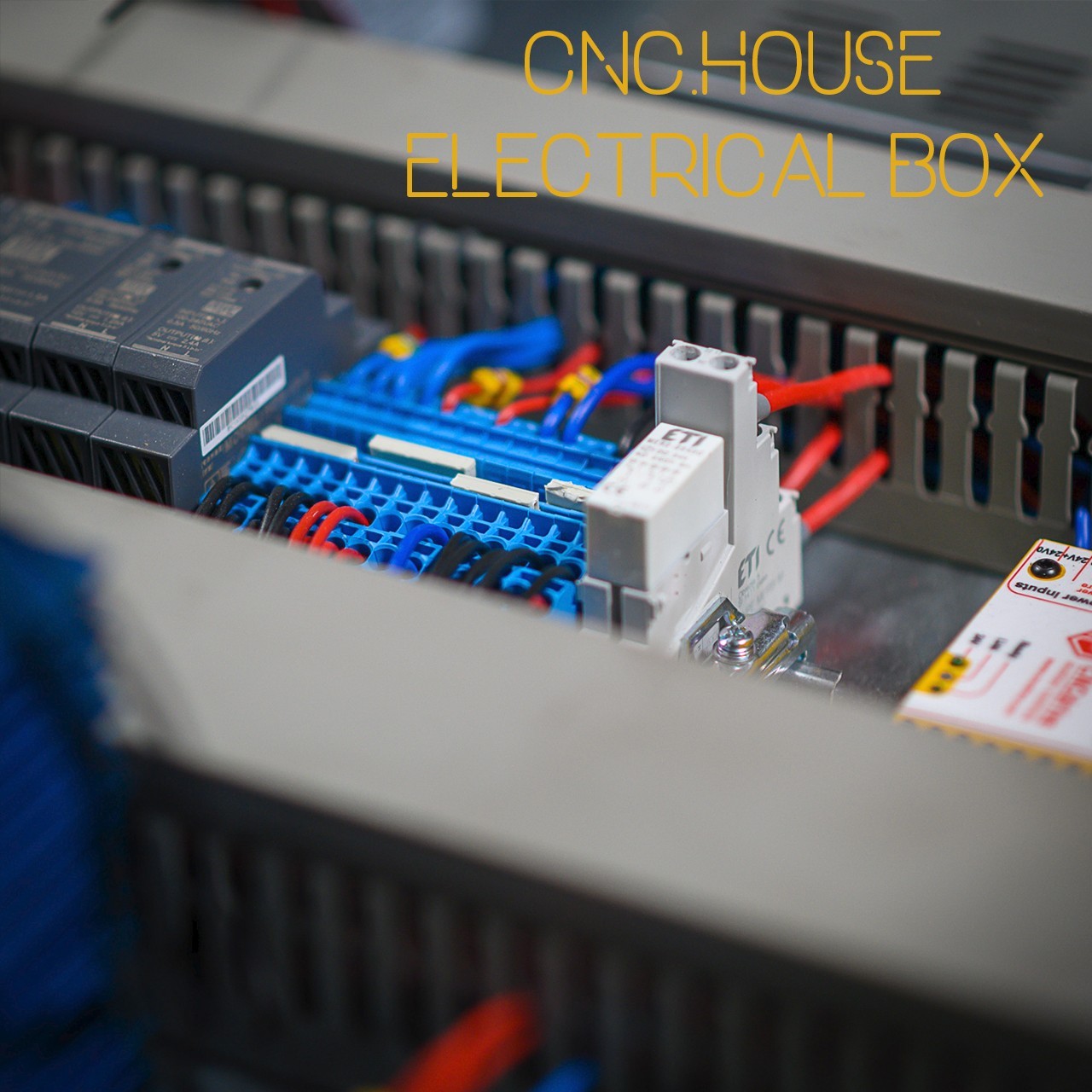

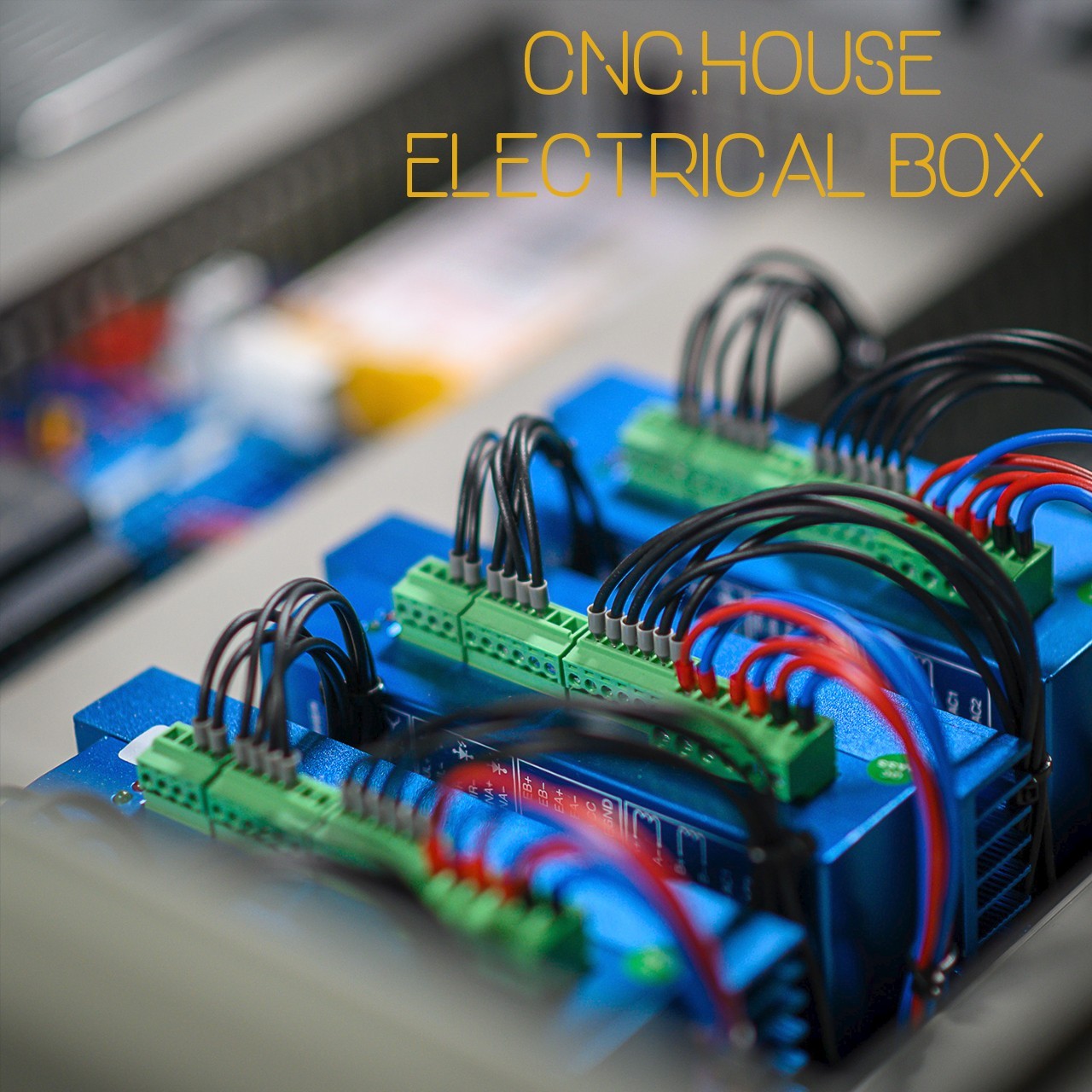

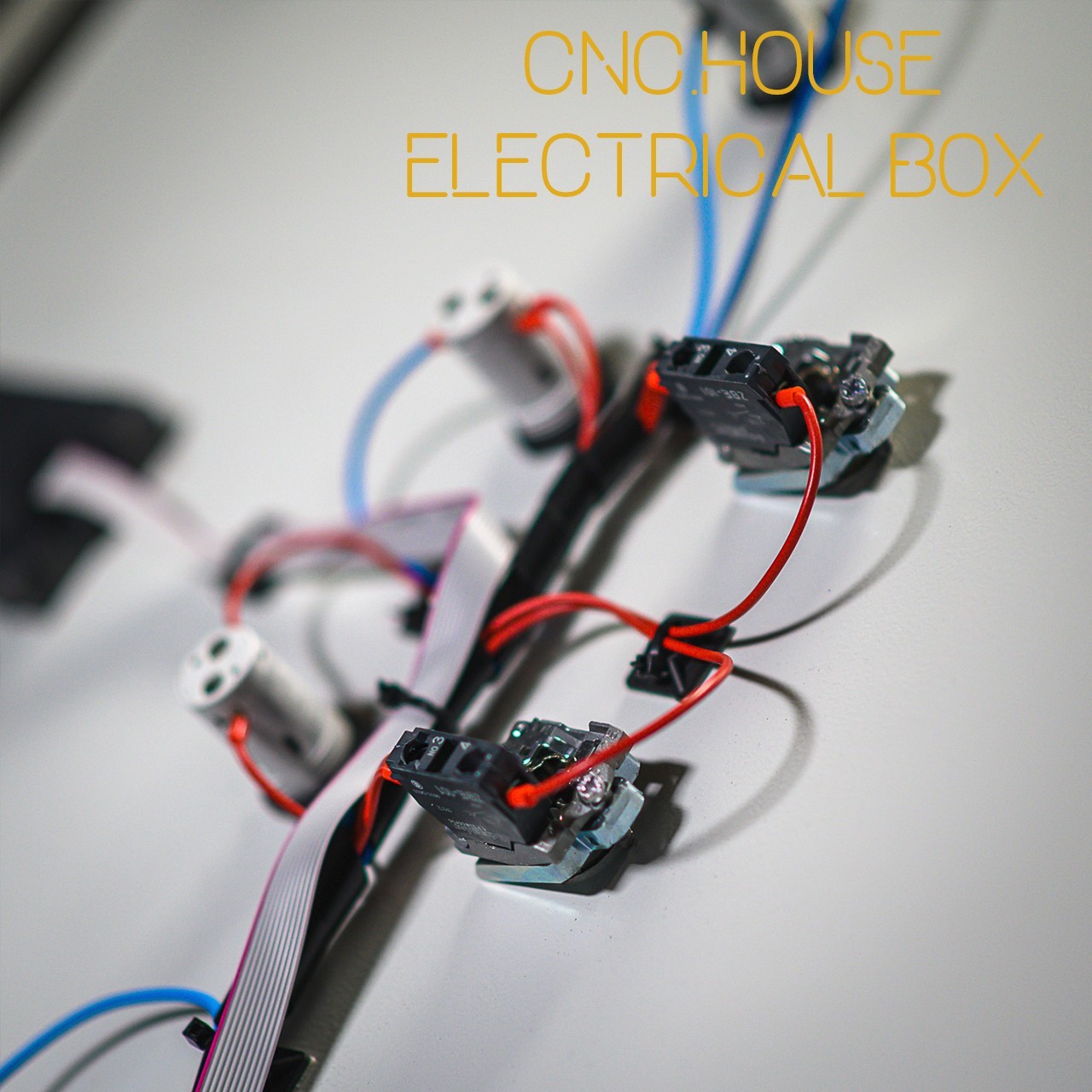

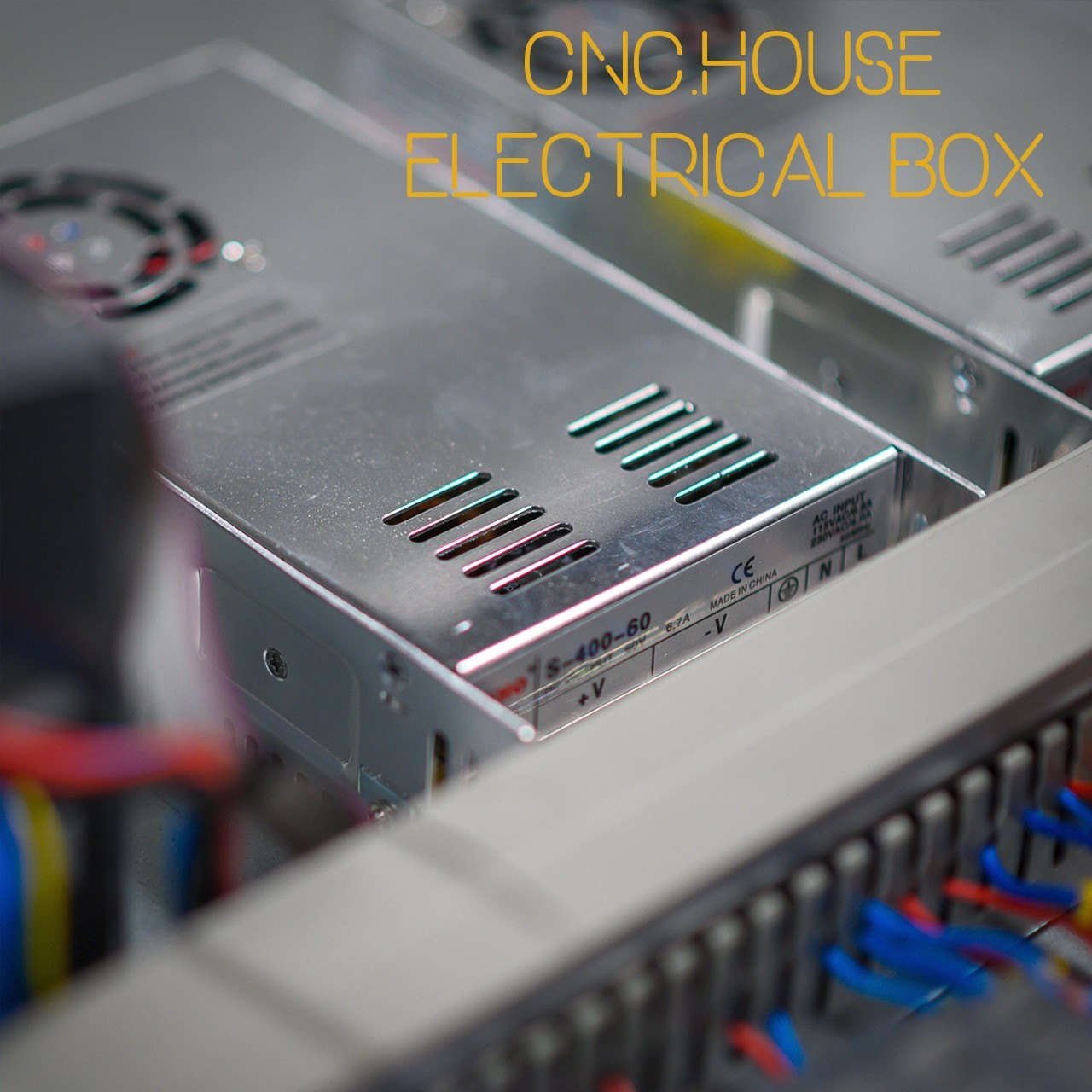

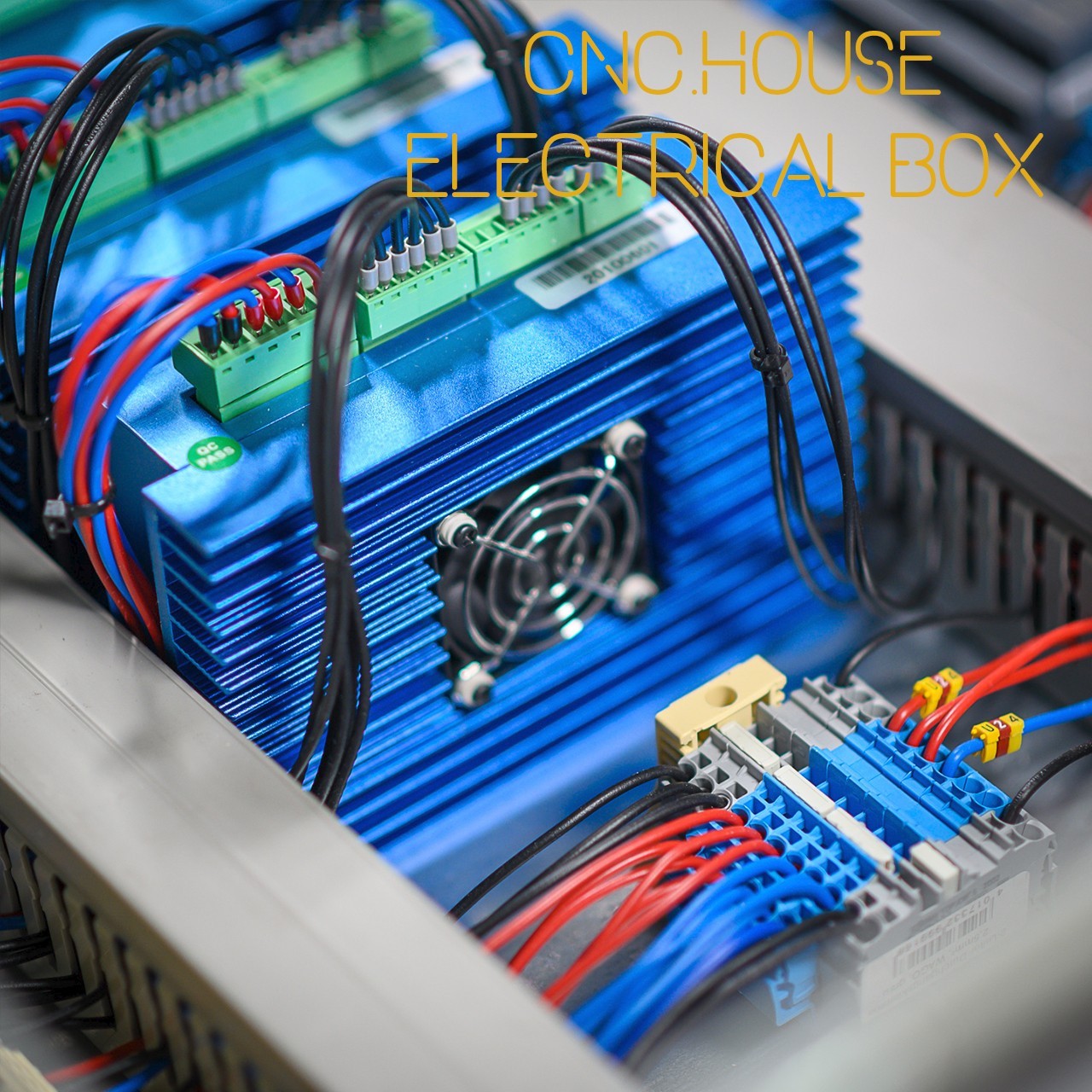

Electrical Cabinet:

A compact and organized electrical cabinet is included to house the machine’s electrical components safely and efficiently.

Controller and Software:

The kit includes an AXBB-E Ethernet Motion Controller, offering seamless control over the CNC machine. Compatible with UCCNC software (license included), you’re provided a user-friendly interface for machine operation.

Designed to satisfy any machining requirements, the Pro Line CNC Kit guarantees precision, quality, and ease of use. Whether you’re an experienced machinist or just starting, our Pro Line CNC Kit is designed to meet and surpass your machining expectations.

Optional Accessories – Edge Finders and Tool Length Sensors (TLS):

To further enhance the precision and versatility of your CNC operations, our kit can be supplemented with high-quality Edge Finders and Tool Length Sensors (TLS). These indispensable tools, manufactured in Europe to strict quality standards, ensure pinpoint accuracy in defining workpiece position and tool length within the machine’s workspace.

Edge Finders: These precision instruments are designed to accurately determine the edges of a workpiece. Our superior quality edge finders ensure precise positioning of your workpiece within the machine – a critical factor for achieving accurate machining results.

Tool Length Sensors (TLS): These high-grade sensors provide precise measurements of tool lengths, enabling the machine to adjust its operations based on the exact dimensions of the tools in use. Our high-precision TLS ensure optimal efficiency and accuracy in your machine’s operations.

Integrating these high-accuracy tools into your CNC kit will significantly elevate your machine’s performance and the quality of its output. With an impressive accuracy level of 0.01 mm, you can confidently take on even the most intricate and demanding projects, secure in the knowledge that your machine operates with supreme precision.

Detailed information:

Motors:

The Pro Line CNC kit is exclusively equipped with the high-performance NEMA 34 Closed Loop Stepper Motors, which are known for their exceptional torque characteristics. These motors deliver a peak torque of 8.5 Nm, which ensures sufficient power for handling even the most demanding machining tasks.

An essential attribute of these motors is their closed-loop design. Unlike traditional stepper motors, closed-loop stepper motors provide real-time feedback on the motor’s position. This allows the motor control system to immediately correct any errors or misalignments, leading to significantly enhanced precision and reliability in all machining processes. This feature is critical in CNC machining where accuracy is paramount.

These NEMA 34 motors are driven by HBS86H 8A Hybrid Drivers. These advanced drivers utilize hybrid servo technology to provide improved motion smoothness and positioning accuracy. They also reduce motor heating, minimize motor vibration, and offer a host of protective features, including over-voltage and over-current protection.

By delivering superior control over motion and positioning, these motors and their associated drivers greatly enhance the precision and quality of your machining operations, making them a crucial component in our Pro Line CNC kit.

Spindle Options:

Our Pro Line kit caters to a wide range of machining requirements by offering a selection of robust and high-performance spindle motors:

- 2.2 kW Water-cooled Spindle Motor: This ER20 spindle motor offers reliable and efficient performance, even under continuous operation. The water-cooled design allows it to maintain optimal temperatures, reducing the risk of overheating and ensuring a longer service life. With a maximum speed of 24000rpm, it guarantees precise machining for a wide array of tasks. It’s paired with a 2.2 kW Inverter VFD 220V D-80, providing efficient power conversion and control.

- 2.2 kW Air-cooled SPINOGY.DE X22 Series Motor: This premium spindle motor features an advanced air-cooled design that ensures efficient heat dissipation, allowing for continuous operation without risk of overheating. The motor achieves up to 24000rpm, providing stability and precision in all your machining processes. It comes with a matching 220V Inverter VFD for efficient power control.

- 3.0 kW Water-cooled Spindle Motor: This powerful ER20 spindle motor offers a high degree of efficiency and reliability. It’s water-cooled design keeps the motor’s temperature under control, ensuring longer lifespan and consistent performance. With a speed of up to 24000rpm, it can handle rigorous machining tasks with precision. The included 3.0 kW Inverter VFD 220V D-100 ensures effective power conversion and control.

- 3.5 kW Water-cooled Spindle Motor: The ER25 spindle motor is our most powerful option. This water-cooled motor ensures optimal temperature management, reducing the risk of overheating and providing stable operation. With a speed of up to 24000rpm, it provides the power and precision necessary for high-load machining. It comes equipped with a 3.5 kW Inverter VFD 220V D-100 for efficient power conversion and control.

Each of these motors is meticulously designed for precision and stability, providing an optimal balance of speed and control to suit your specific machining needs. The paired Inverter VFDs further enhance the efficiency and control of these spindle motors, leading to a smooth and reliable machining process.

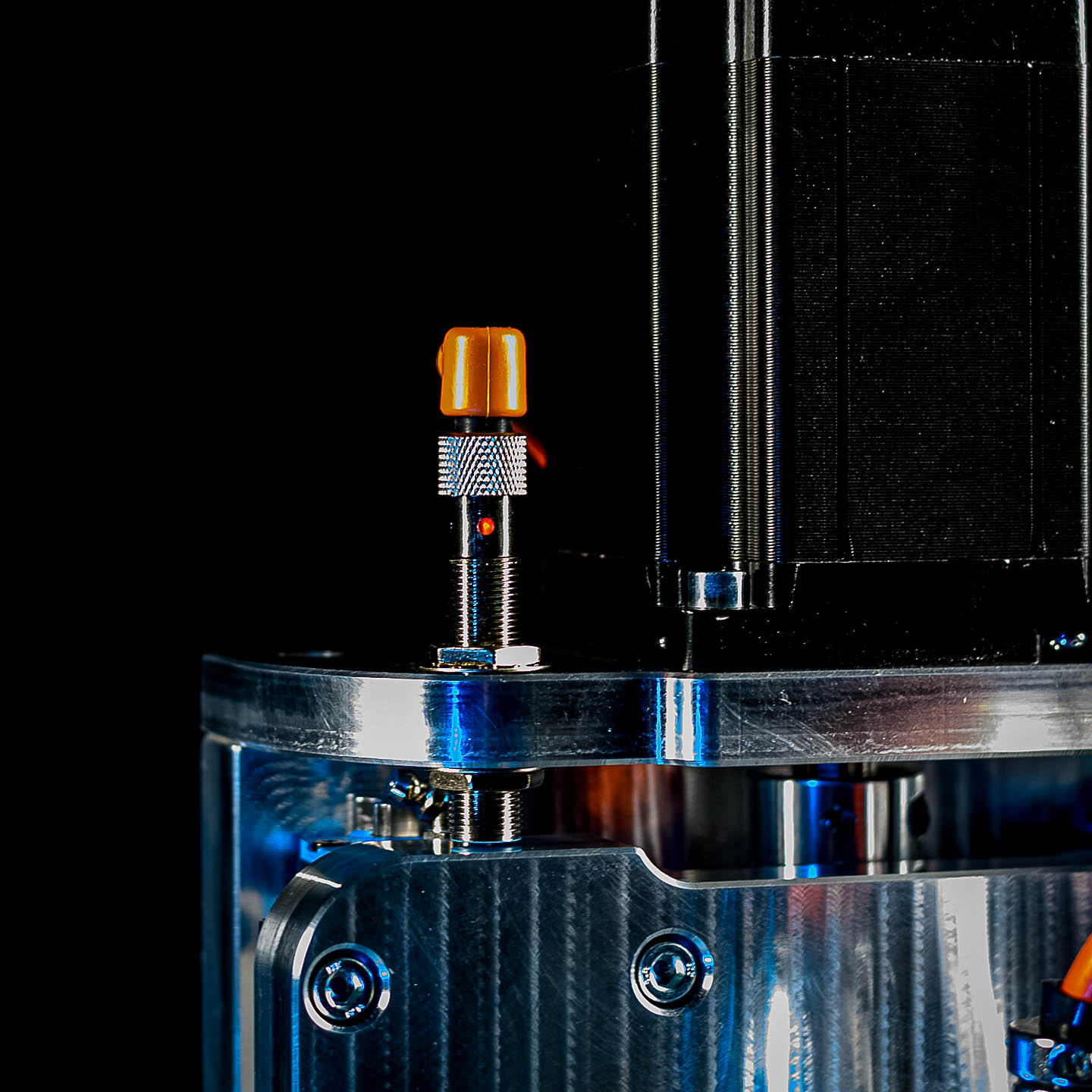

Edge finders / Tool length sensors (TLS):

High-Quality Edge Finders / Tool Length Sensors (TLS):

In CNC machining, precision is everything. That’s why our CNC Kit includes high-quality Edge Finders and Tool Length Sensors (TLS) as part of the package.

These tools are essential for accurate machining operations. They allow you to determine the exact position of your workpiece and tool length within the machine’s workspace with a high degree of precision. This ensures that your machine operates accurately and produces precise, high-quality results.

Our edge finders and TLS are manufactured in Europe, adhering to stringent quality standards. They offer an impressive accuracy level of 0.01 mm, ensuring that your CNC machine operates with the utmost precision.

Edge Finders: These devices are used to locate the edges of a workpiece accurately. Our high-quality edge finders ensure that you can set your workpiece in the correct position within the machine, a critical factor in achieving accurate machining results.

Tool Length Sensors (TLS): Our top-of-the-line TLS provide precise measurements of tool lengths. This is vital in CNC machining, as it allows the machine to adjust its operations based on the exact dimensions of the tools in use. By using our high-precision TLS, you can ensure that your machine operates with maximum efficiency and accuracy.

Incorporating these high-precision devices into your CNC kit will significantly enhance your CNC machine’s performance and output quality. With the assurance of accuracy to the hundredth of a millimeter, you can confidently tackle even the most intricate and demanding projects.

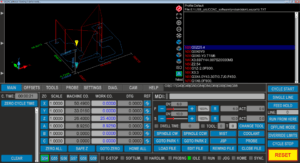

Controller and Software:

The AXBB-E ethernet motion controller and breakout board is a remarkable piece of technology that serves as the command center of your CNC Kit. It is a combined solution, offering both motion control and breakout board capabilities in one single, compact unit. This controller works seamlessly with popular software platforms such as UCCNC, Mach3, and Mach4.

Key Features of AXBB-E Ethernet Motion Controller and Breakout Board:

- Complete motion controller and breakout board solution in a single board.

- Multiple optically isolated and non-isolated outputs and inputs, providing various control capabilities.

- LED indicators on isolated I/Os.

- 24 Volts capable isolated I/Os.

- It can control machine tools with stepper or servo motor controls with step and direction interfaces.

- The controller can output a maximum of 400kHz stepping frequency and can work with up to 6-axes.

- Configurable I/Os, allowing for customization as per application requirements.

In terms of software capabilities, this controller can execute RS274 G and M codes and offers an unlimited number of user text macros with a flexible script engine. It provides real-time 3D toolpath viewing and supports OpenGL, ensuring fast screen update rates with low CPU/GPU usage. It also includes a built-in visual screen editor, allowing users to customize the screen fully.

The controller also supports parametric programming using internal variables and programming mathematical expressions. It includes a basic CAM module for DXF files import and offers Modbus TCP, RTU, and ASCII communication support via Modbus plugin. Moreover, it supports various plugins and functionalities, such as fast laser scan type engraving plugin, webcamera plugin, Xbox360 controller plugin, 3D printer plugin, and more.

This device is being continuously and actively developed and maintained, ensuring that it remains up-to-date with the latest technological advancements. It’s compatible with Windows XP, 7, 8, 8.1,10 on all both 32 and 64bit versions.

For more information on the AXBB-E Ethernet Motion Controller and Breakout Board, please visit the manufacturer’s website: https://www.cncdrive.com/

Please note that it is always recommended to consult with the manufacturer or a qualified professional when setting up your CNC kit to ensure that it is configured correctly for your specific needs.

UCR201 wireless CNC jog pendant:

Navigating your CNC machine operations with ease and precision is a must for any serious machinist. The UCR201 wireless CNC jog pendant is an exceptional device designed to enhance your control over the CNC machining process. This tool is compatible with UCCNC and Mach3 software, allowing for seamless integration with your existing setup.

Key Features of UCR201 Wireless CNC Jog Pendant:

- Wireless Connectivity: The UCR201 offers wireless control of your CNC machine, allowing for flexible operation without the constraints of wires. The pendant boasts an impressive transmit range of 10-15 meters, depending on the environment.

- Multi-Axis Control: This pendant supports up to 6-axis on-screen, giving you comprehensive control over your CNC machine.

- Large LCD Screen: The UCR201 features a large LCD screen with backlighting, allowing for easy reading of information even in low-light conditions.

- Industrial Wheel Encoder: This feature allows for precise, tactile control over your machine’s movements, increasing the accuracy of your operations.

- USB Wireless Transmitter: The pendant connects to your control PC via a USB wireless transmitter, providing a reliable and fast connection.

- Free Wireless Channel Frequency Operation: This feature ensures higher transmit range than wifi, ensuring a stable connection throughout your workspace.

- Function and Custom Pushbuttons: The UCR201 comes with function and custom pushbuttons, allowing you to customize your controls for a tailored machining experience.

- Enable Safety Buttons: Safety is paramount in any machining operation. The UCR201 features enable safety buttons on both sides of the pendant for easy access.

- Battery Operation: The UCR201 operates on batteries, offering long life and easy replacement when necessary.

The UCR201 wireless CNC jog pendant is a game-changer for CNC machining, offering precision control, ease of use, and flexibility. Its wireless design allows for smooth navigation around your workspace without the constraints of a wired connection, making it an excellent addition to your CNC Kit with Closed Loop Stepper Motors and Ethernet Motion Controller – Standadr Line.

Pro Line CNC Kit – Rack Drive System for Large Format Machining