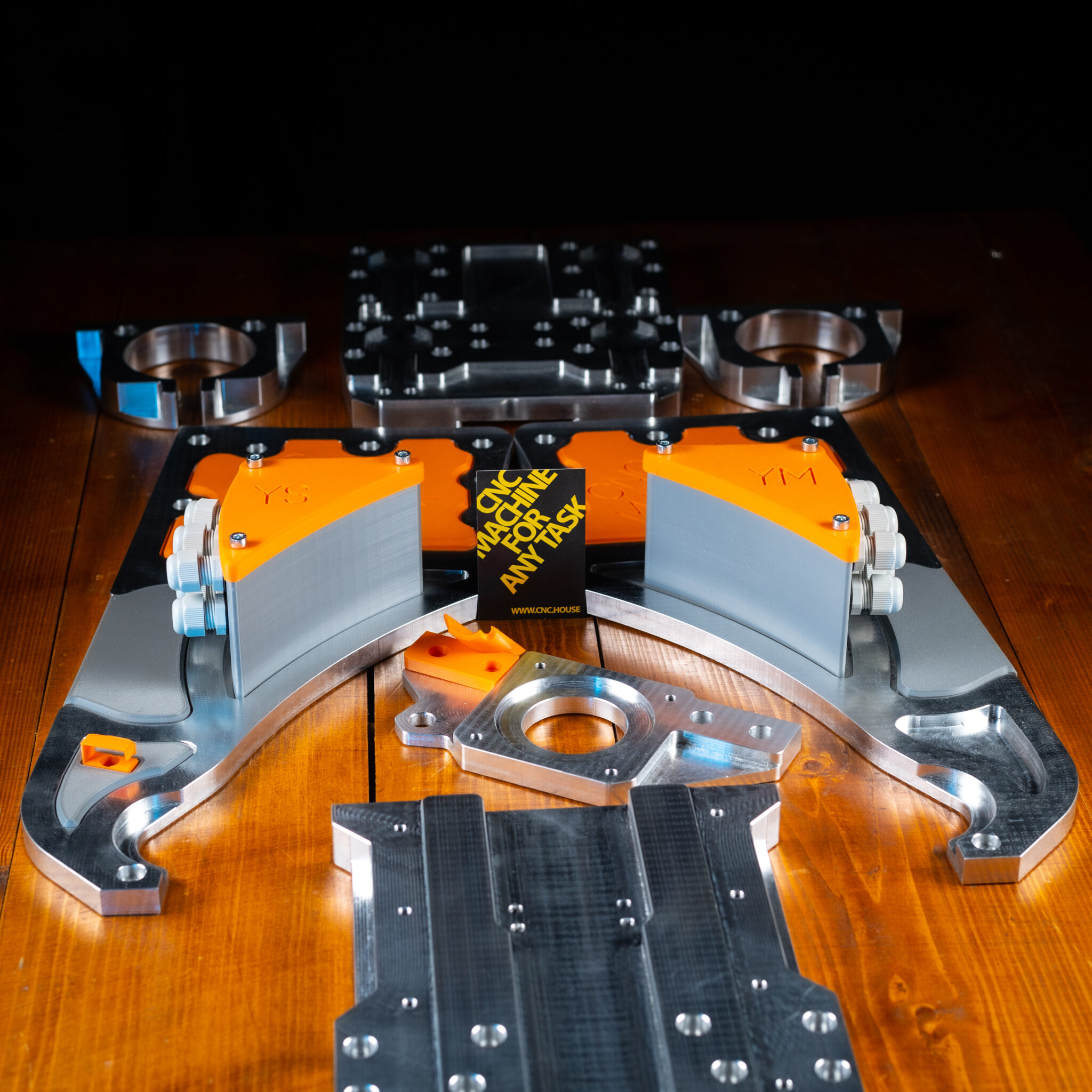

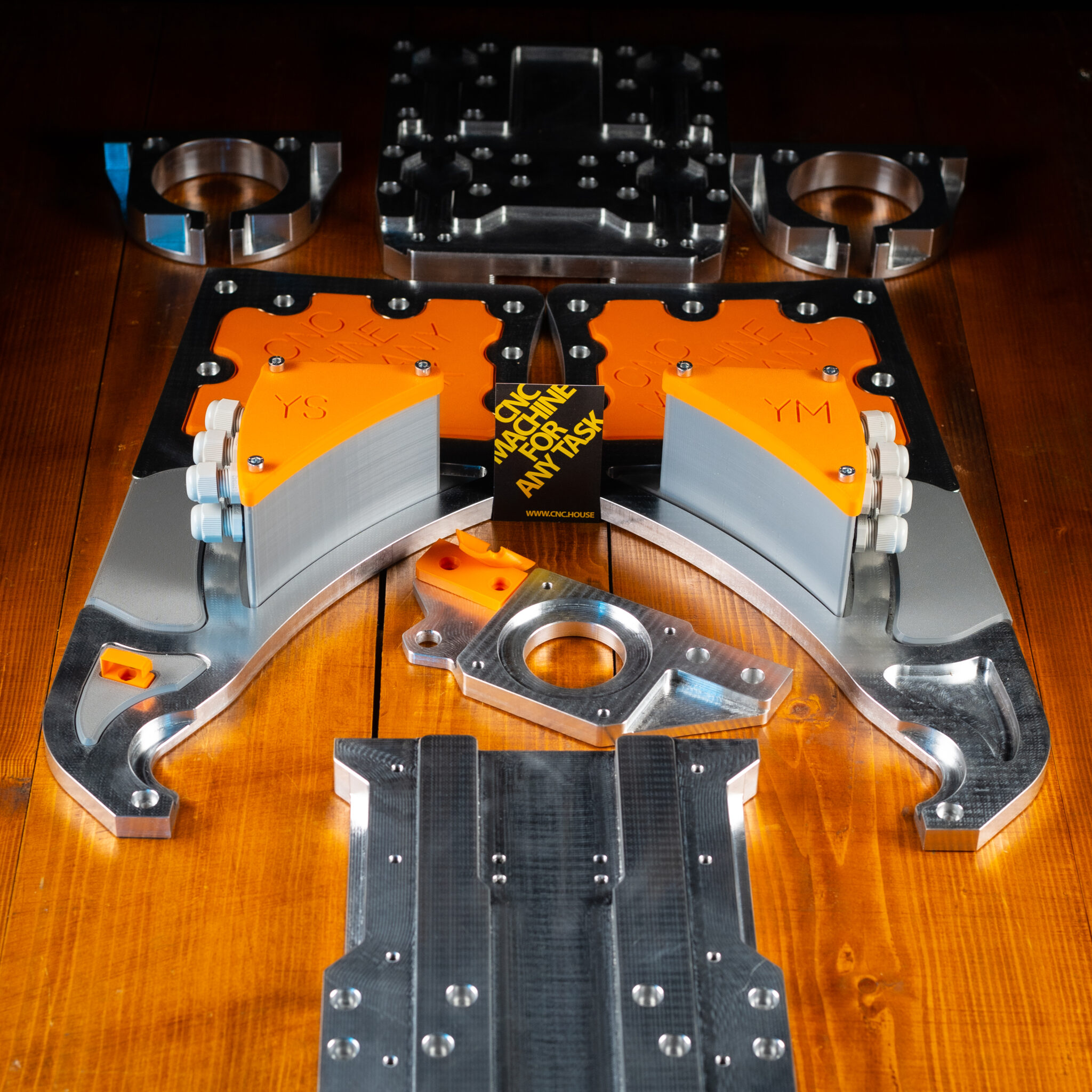

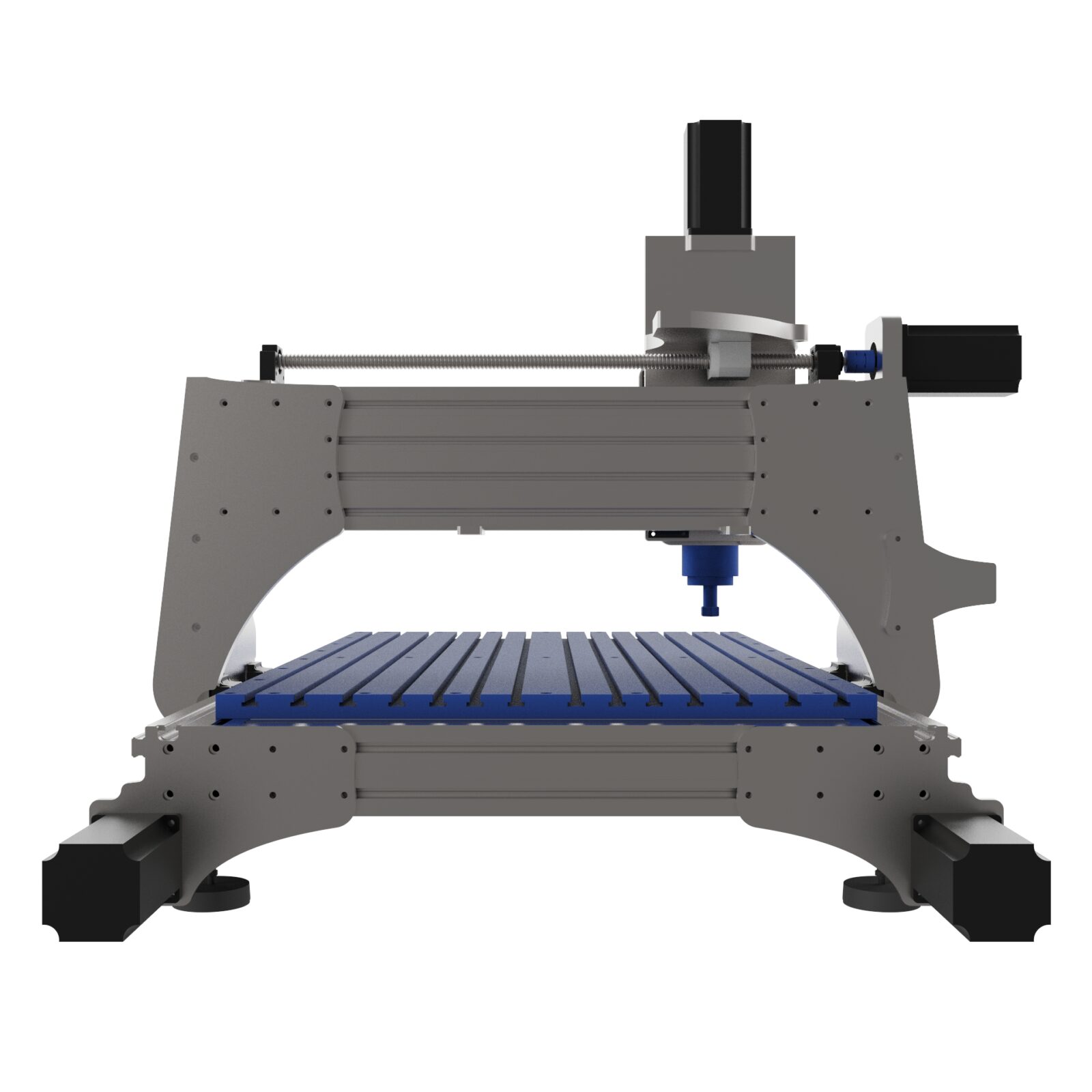

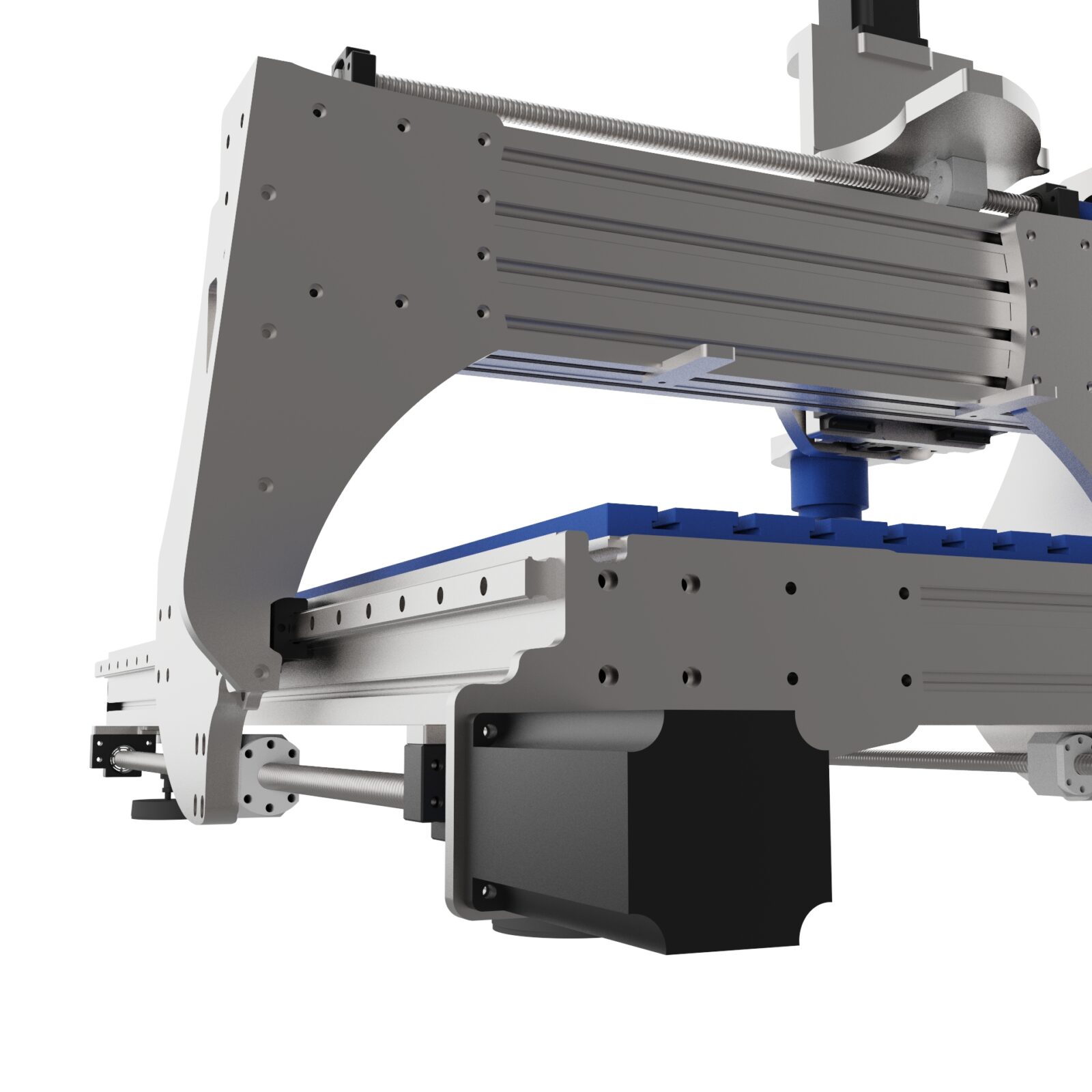

The Pro Line CNC Mechanical Assembly Kit is a comprehensive package that contains all you need to build a robust, high-performance CNC machine. From precision-milled plates to the specification of elements and fasteners, we ensure every single detail is meticulously addressed. Let’s delve deeper into the components of this kit:

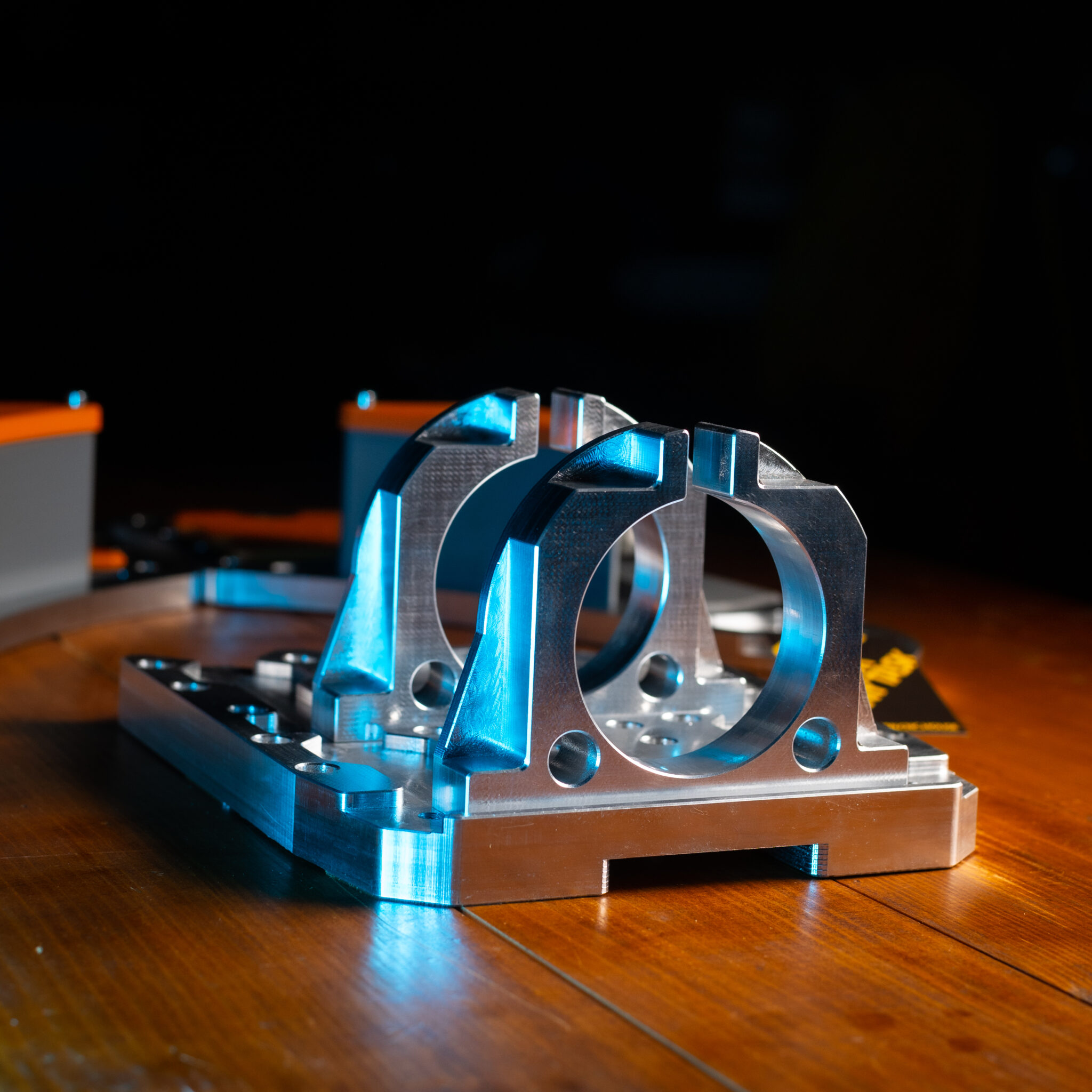

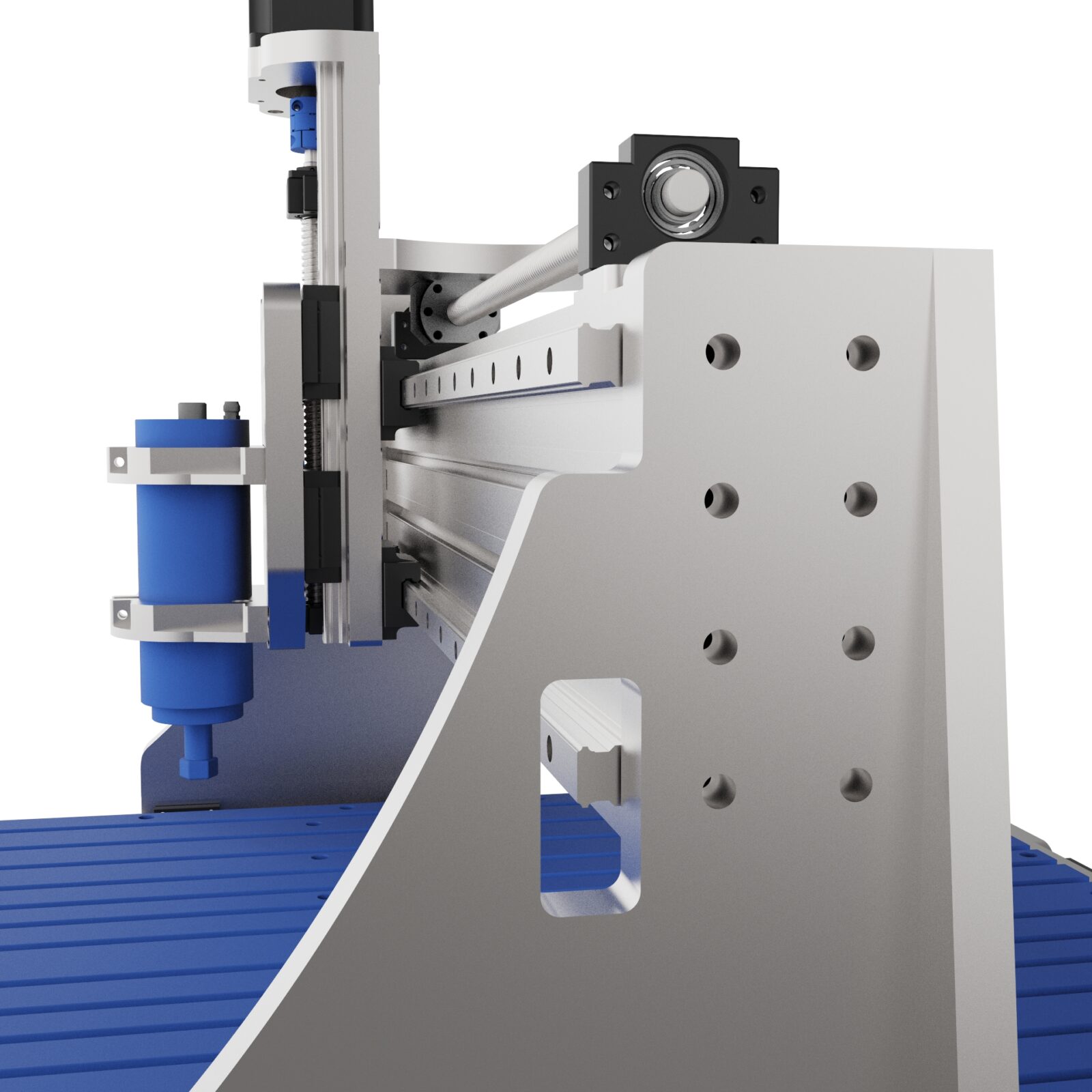

Milled Plates:

This kit comes with meticulously machined aluminum plates. These plates form the primary structure of the CNC machine, offering remarkable rigidity and durability. Precision-machined from high-quality aluminum, they ensure perfect alignment and fit, contributing to utmost accuracy and repeatability during machining operations. They are designed to withstand the stresses of aggressive machining modes, minimizing potential deformation and maximizing longevity.

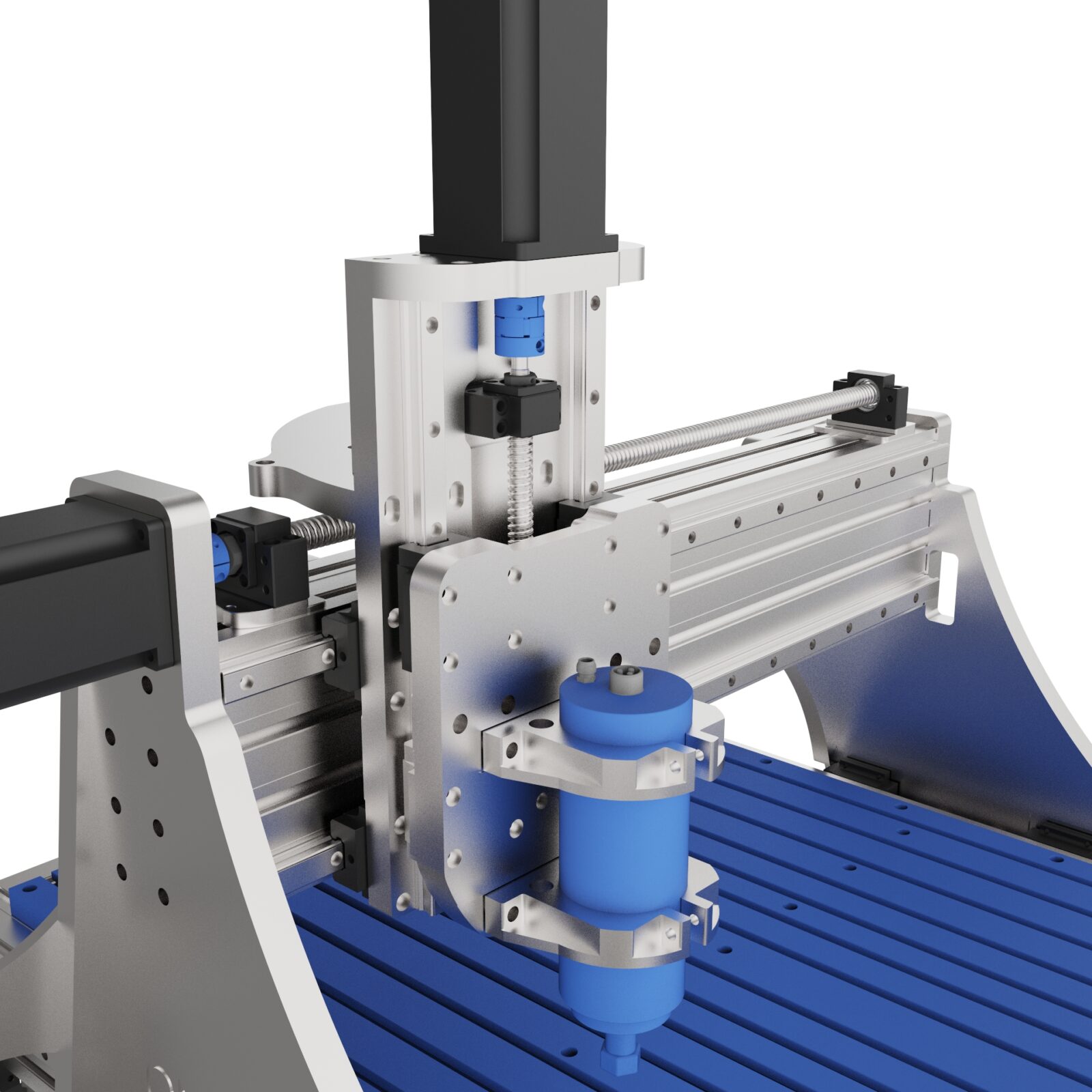

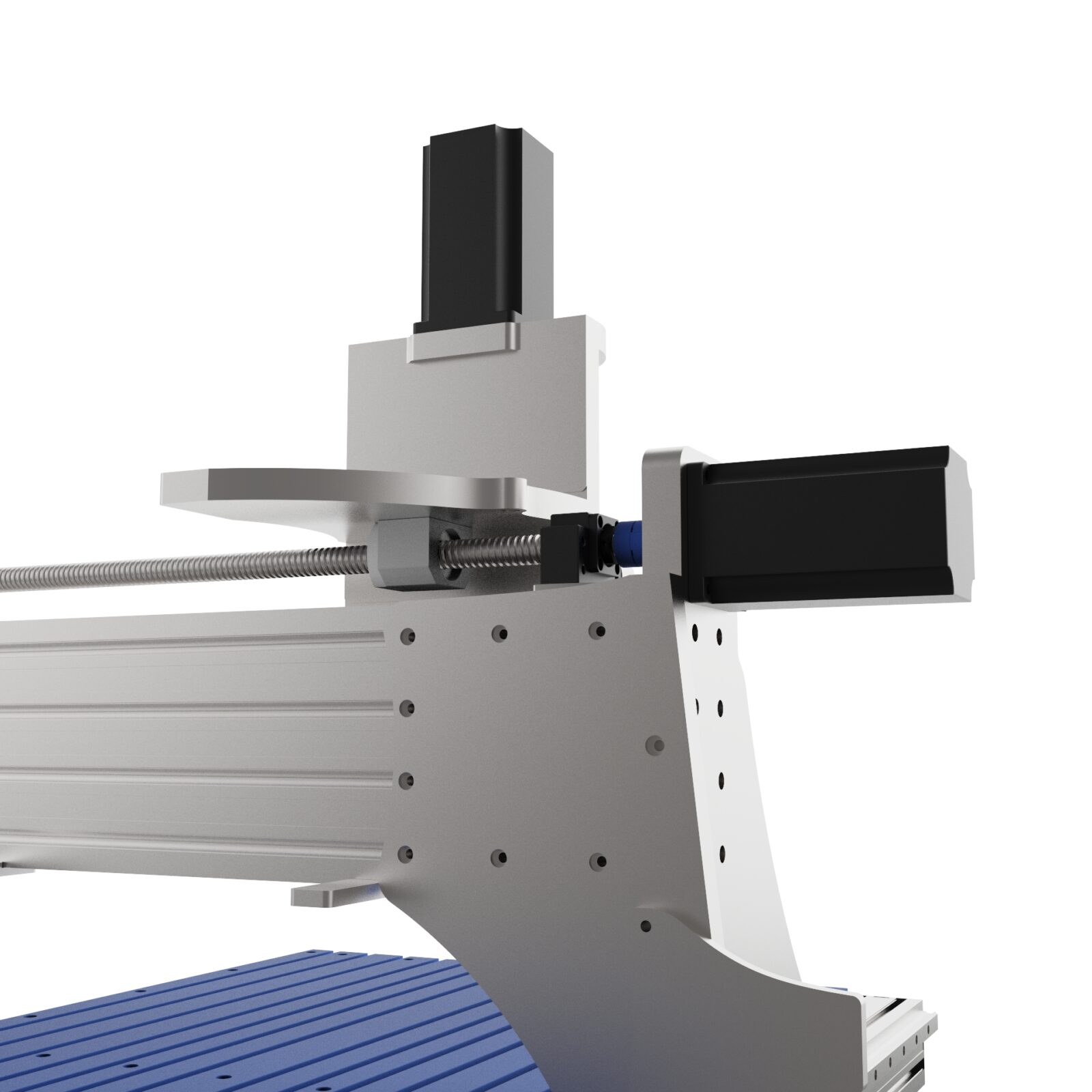

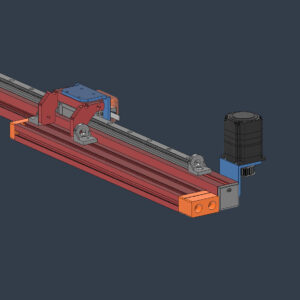

Ball Screws and Nuts:

The Pro Line CNC Mechanical Assembly Kit is equipped with the following types of ball screws and nuts:

- Z Axis – Ballscrew 1605/1610

- X Axis – Ballscrew 2005/2010

- Y Axis – 2 x Ballscrew 2005/2010

These components provide low friction movement and extraordinary positioning accuracy, a crucial factor for precision machining.

Motor Compatibility:

While our project was originally developed for the NEMA 34 stepper motor or closed-loop type, it can be adapted for various other motor types according to your specific requirements. Please let us know if your motor type isn’t listed in the order options, and we’ll be more than happy to accommodate your needs.

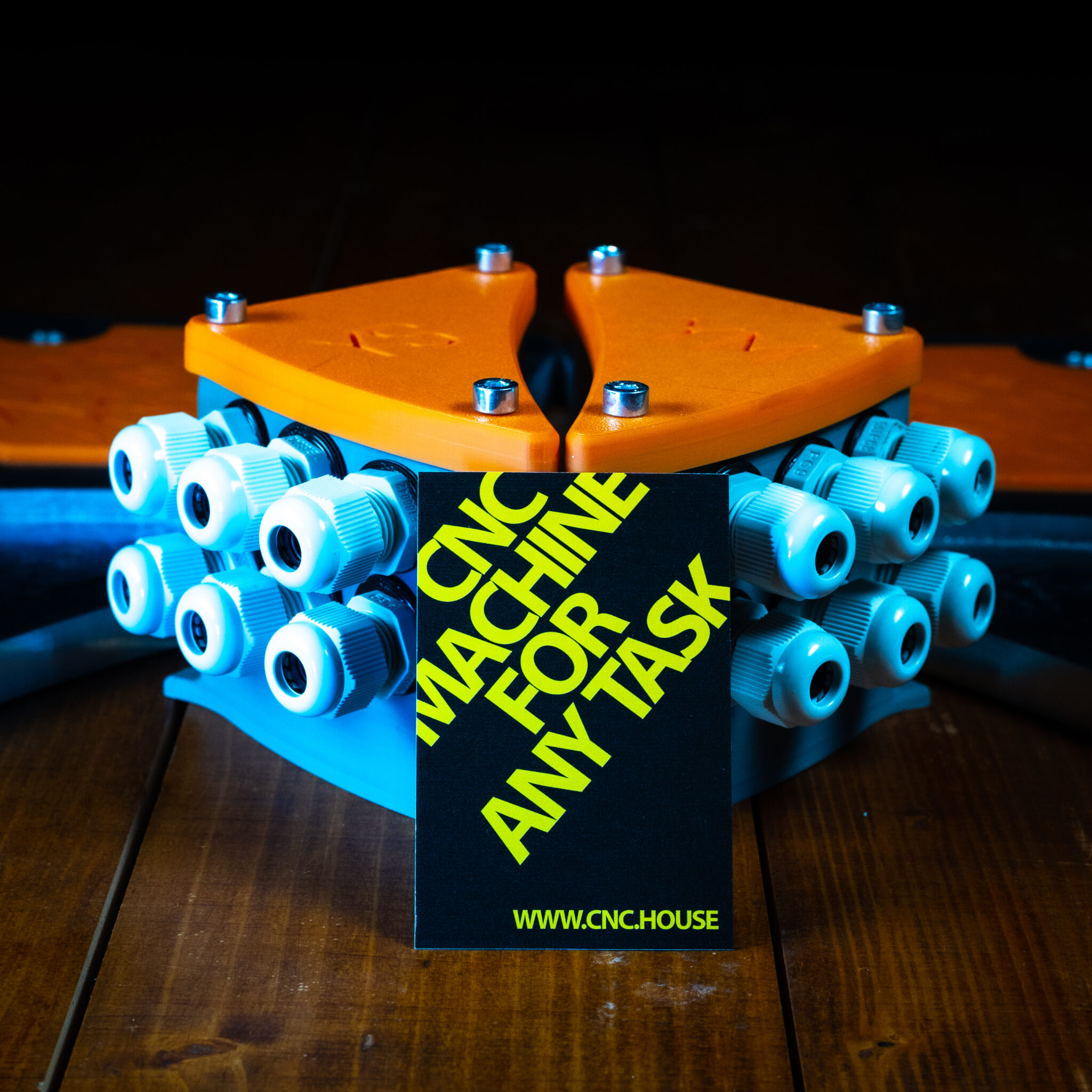

Sensors:

Our project utilizes M12 inductive sensors. A total of 4 sensors are needed:

- Z Axis – 1 inductive sensor for Home and Z+ limit

- X Axis – 1 inductive sensor for Home and X+/- limits

- Y Axis – 3 inductive sensors for Home and Y+/- limits

This kit includes step-by-step assembly instructions to ensure a smooth building process. Please note that this is a mechanical kit, and motors and sensors are not included.

Package Inclusions:

The kit includes all the milled plates required to build your CNC machine, along with a complete specification of elements and fasteners. The full list can be found below. Also included are step-by-step assembly instructions to guide you throughout the build process.

We at CNC.HOUSE understand the nuances of CNC machining and have thus tailored this kit to meet and exceed your machining needs. Our commitment lies in delivering high-performing, reliable, and durable CNC machines, and this kit is a step in that direction.