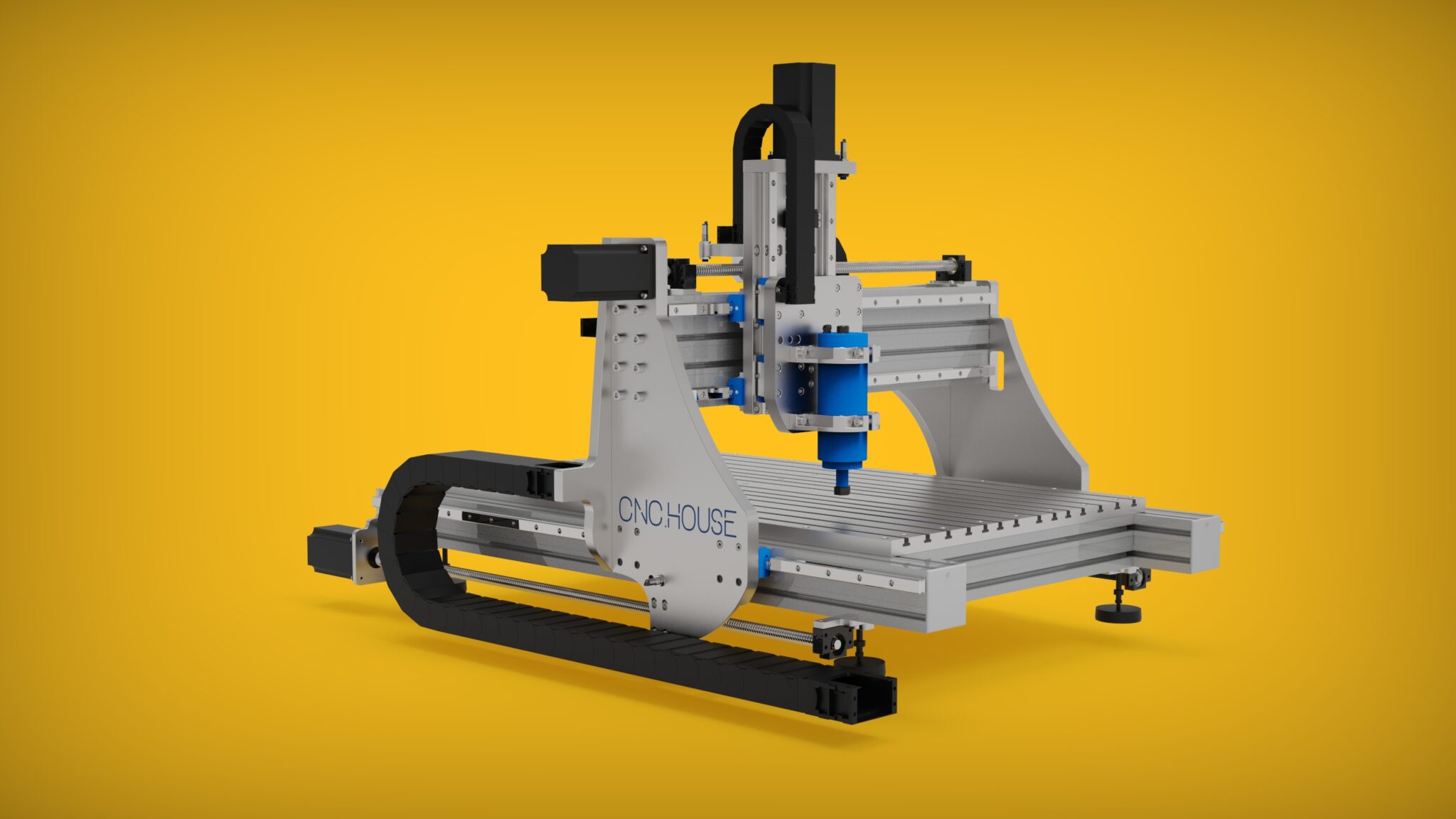

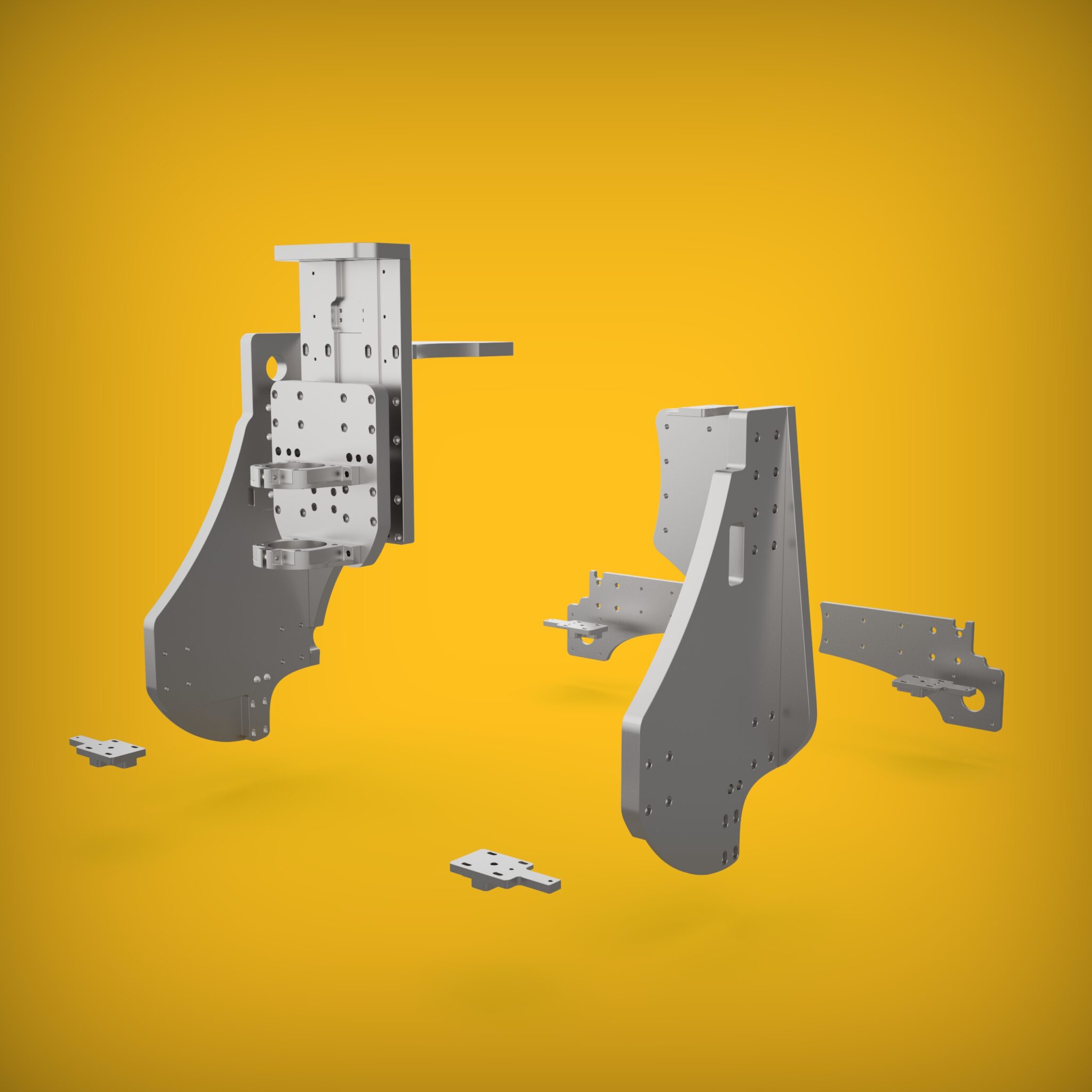

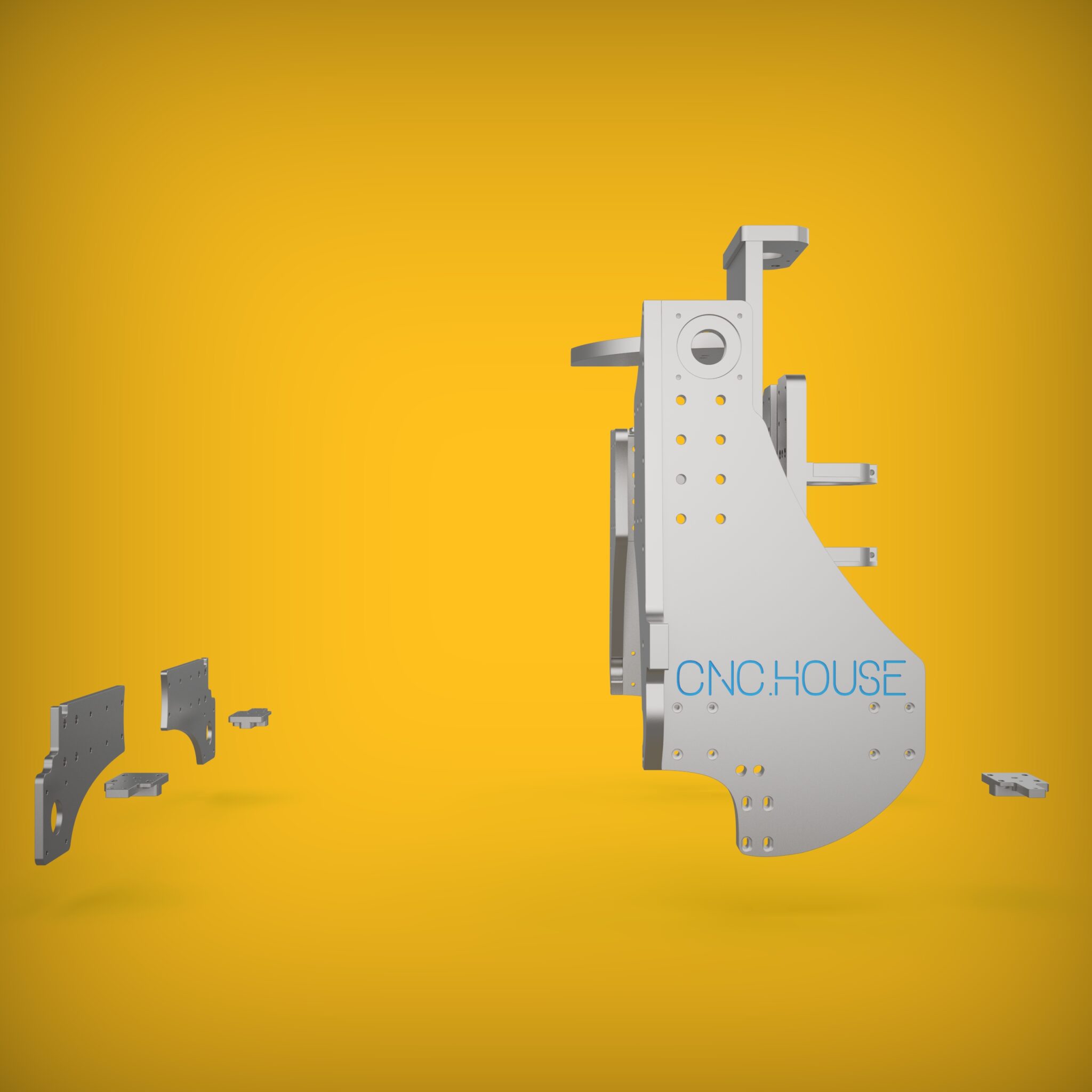

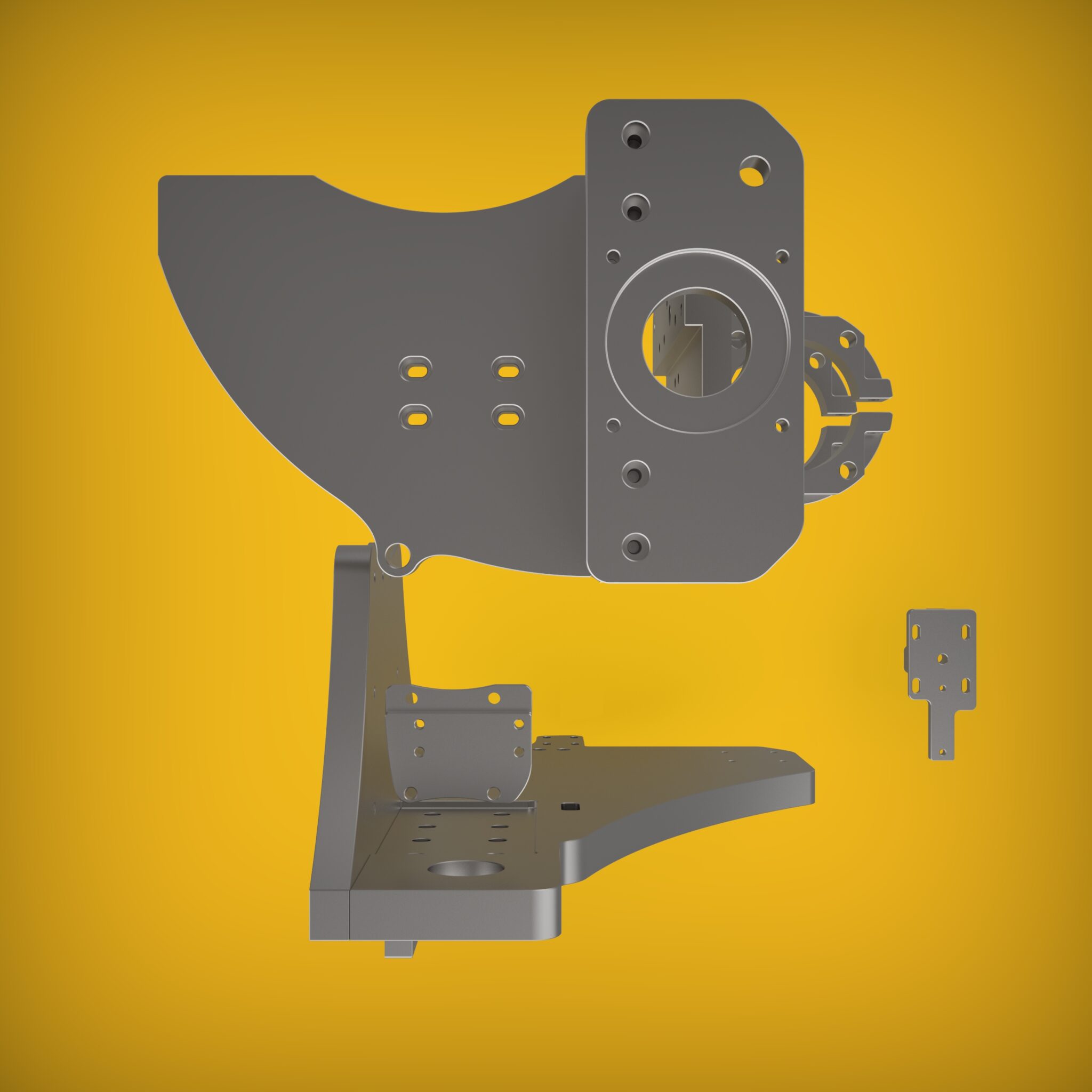

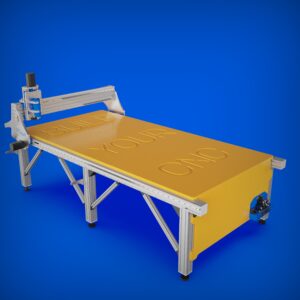

The Pro Line CNC Milling Machine 3D Model is a comprehensive resource for hobbyists and professionals looking to build their own CNC milling machine with industrial-grade capabilities. This model is meticulously designed in Autodesk Fusion360, a highly regarded design software, offering superior precision and ease of use.

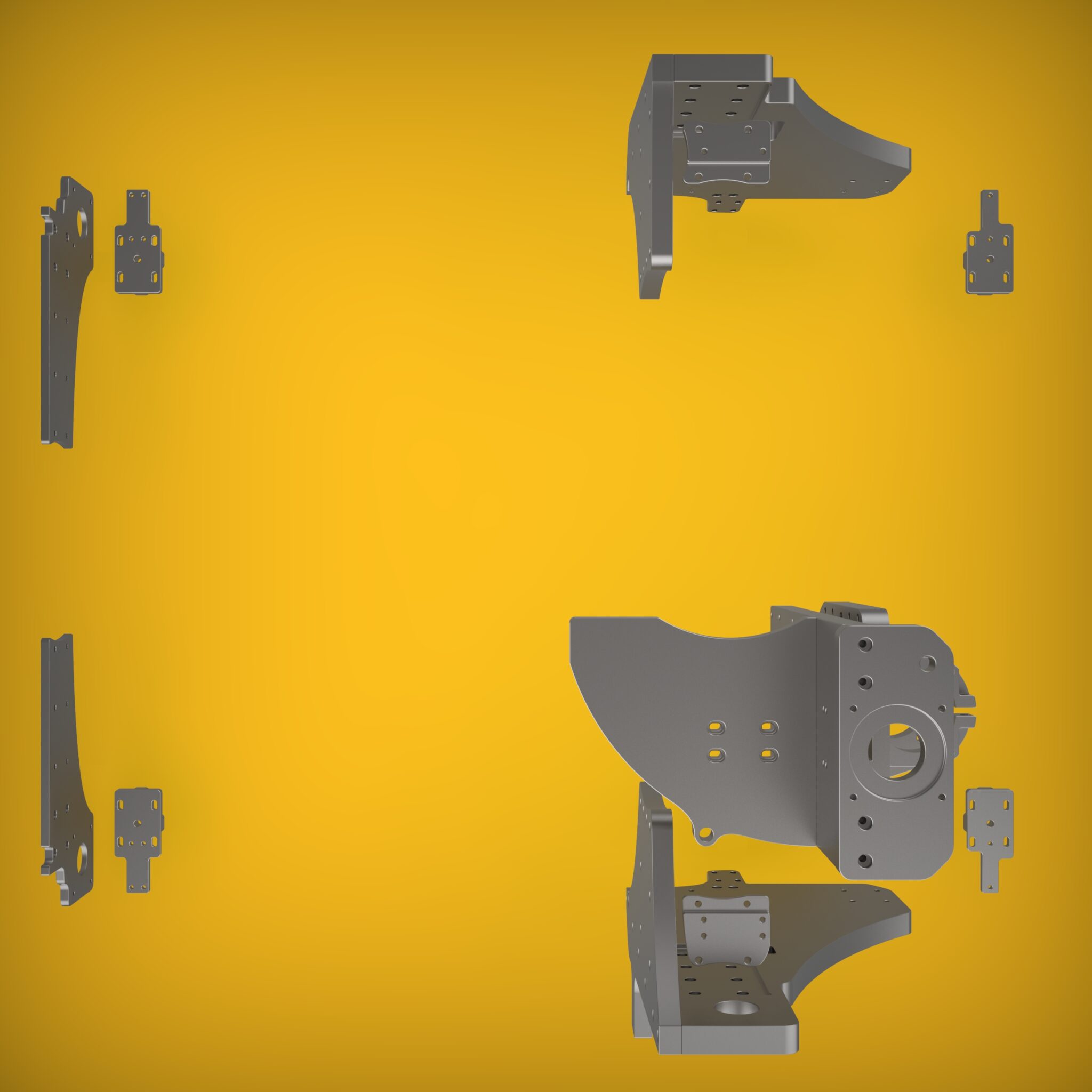

Key Specifications:

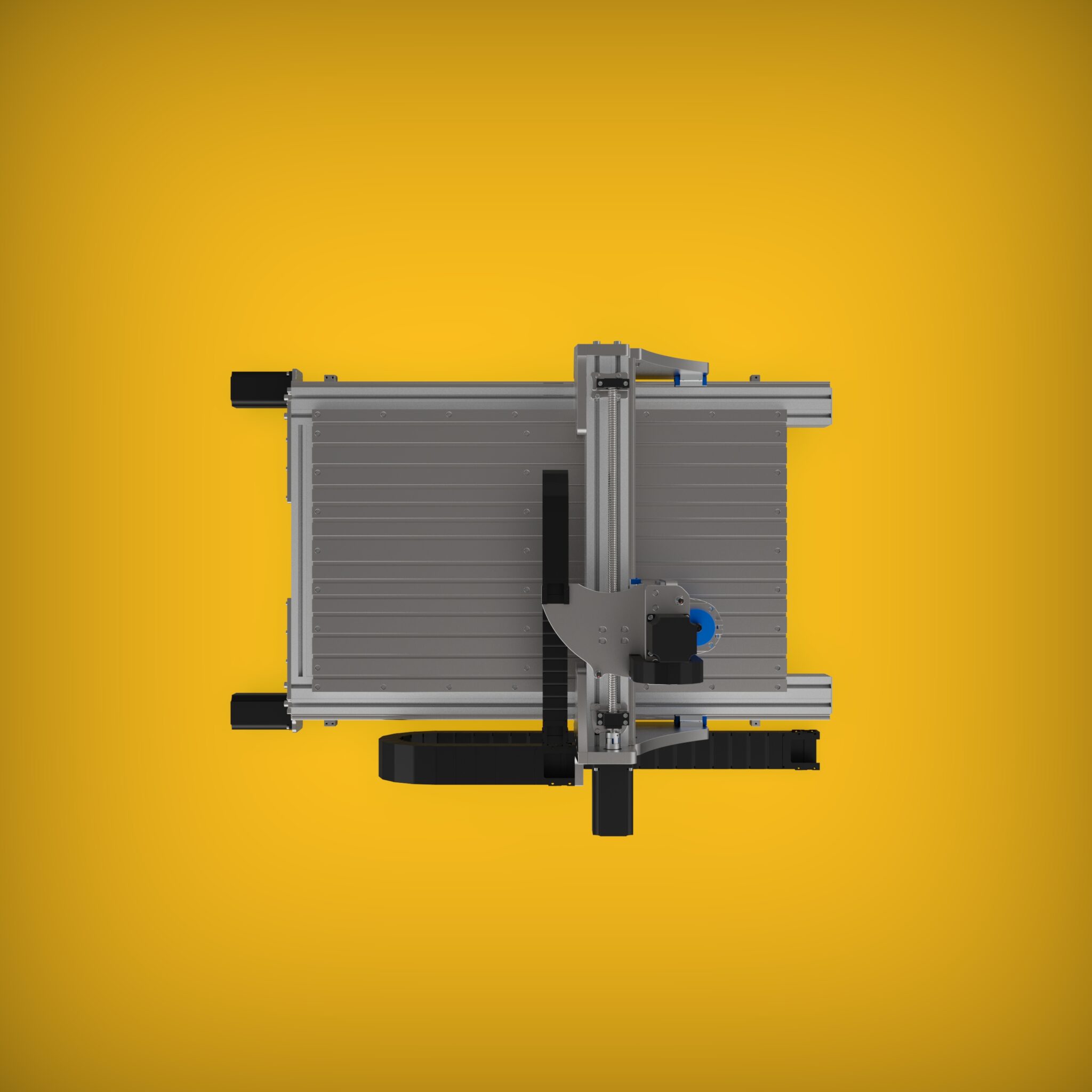

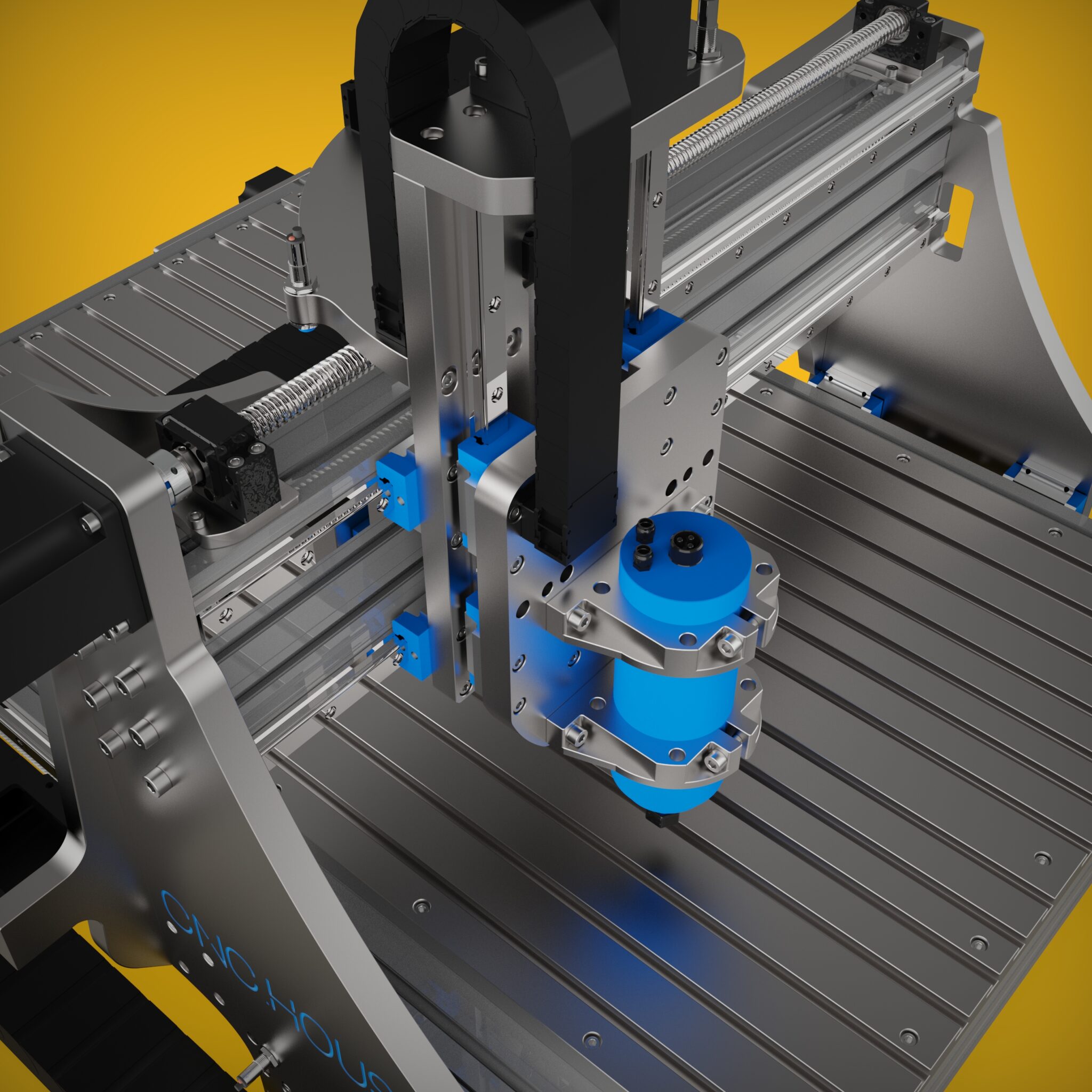

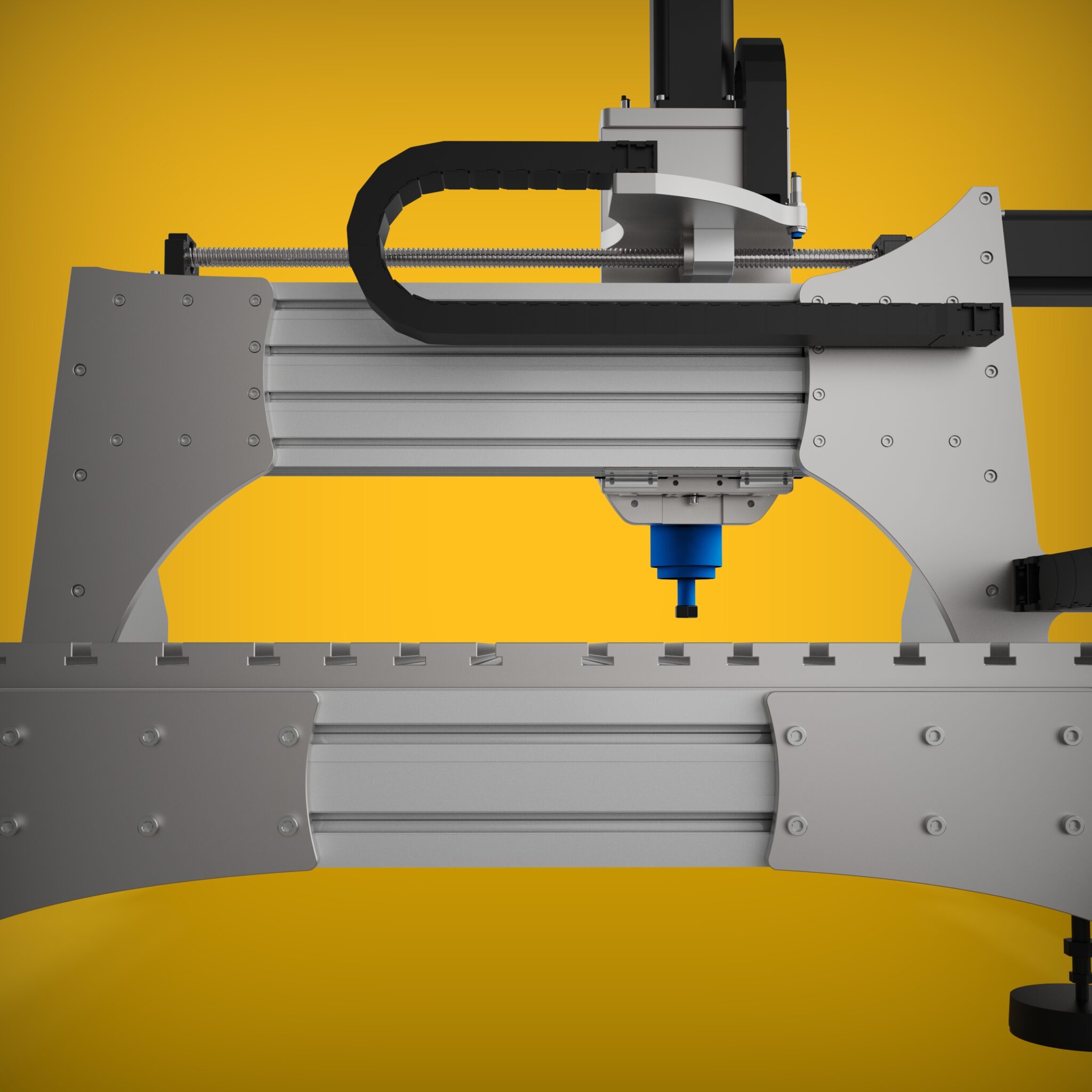

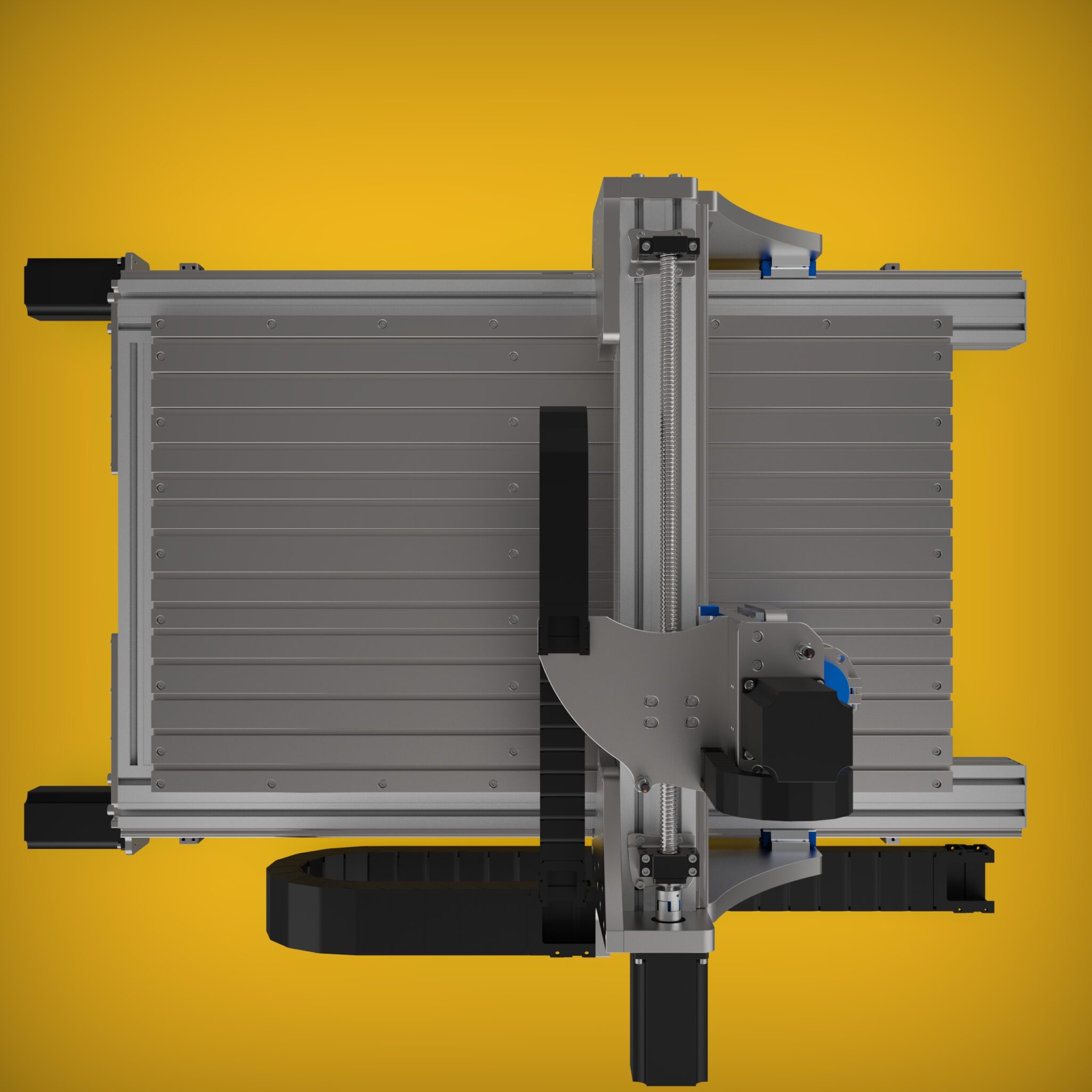

- Working Area: The CNC milling machine built from this model provides a sizable working area of 900mm x 600mm x 160mm, giving you ample space for various machining tasks.

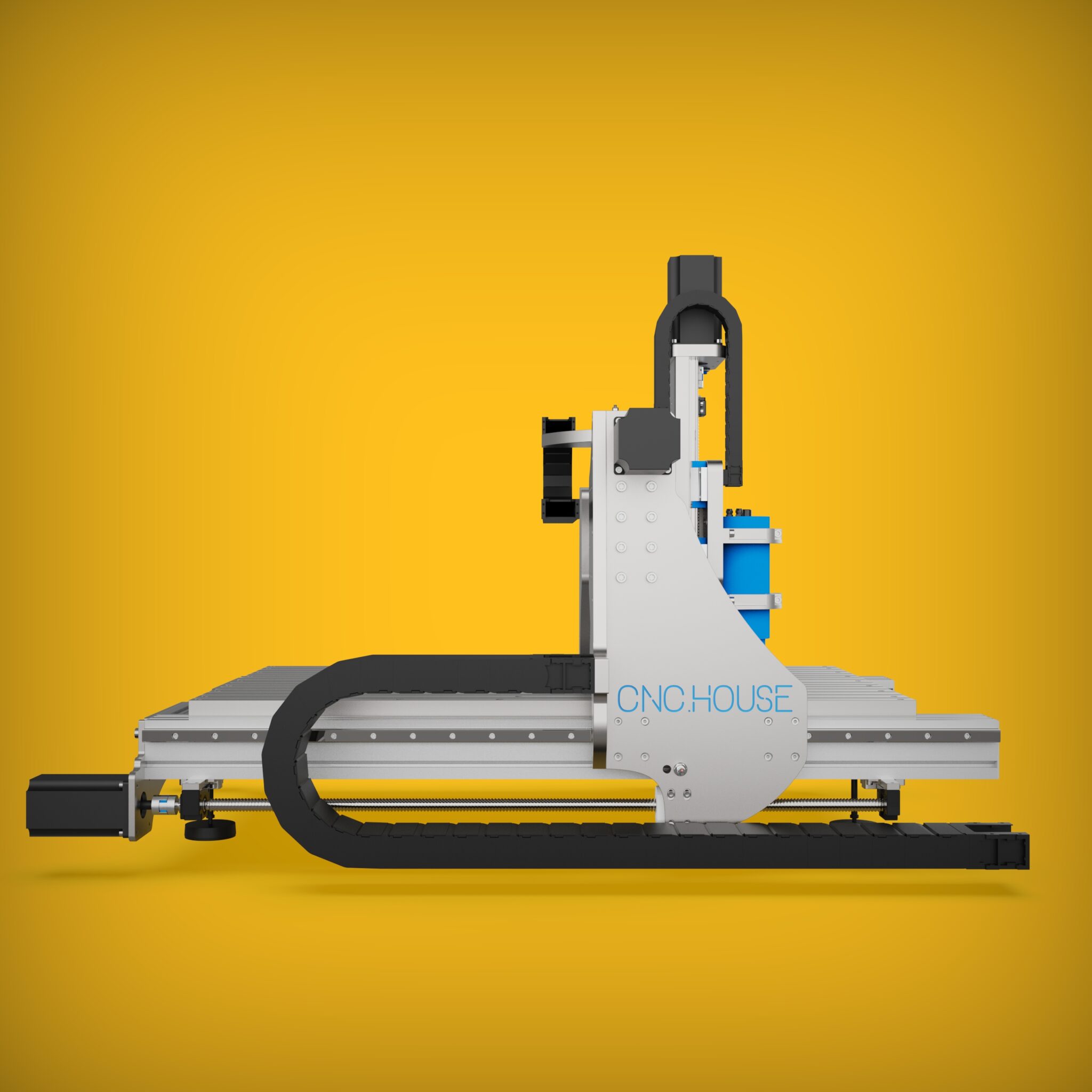

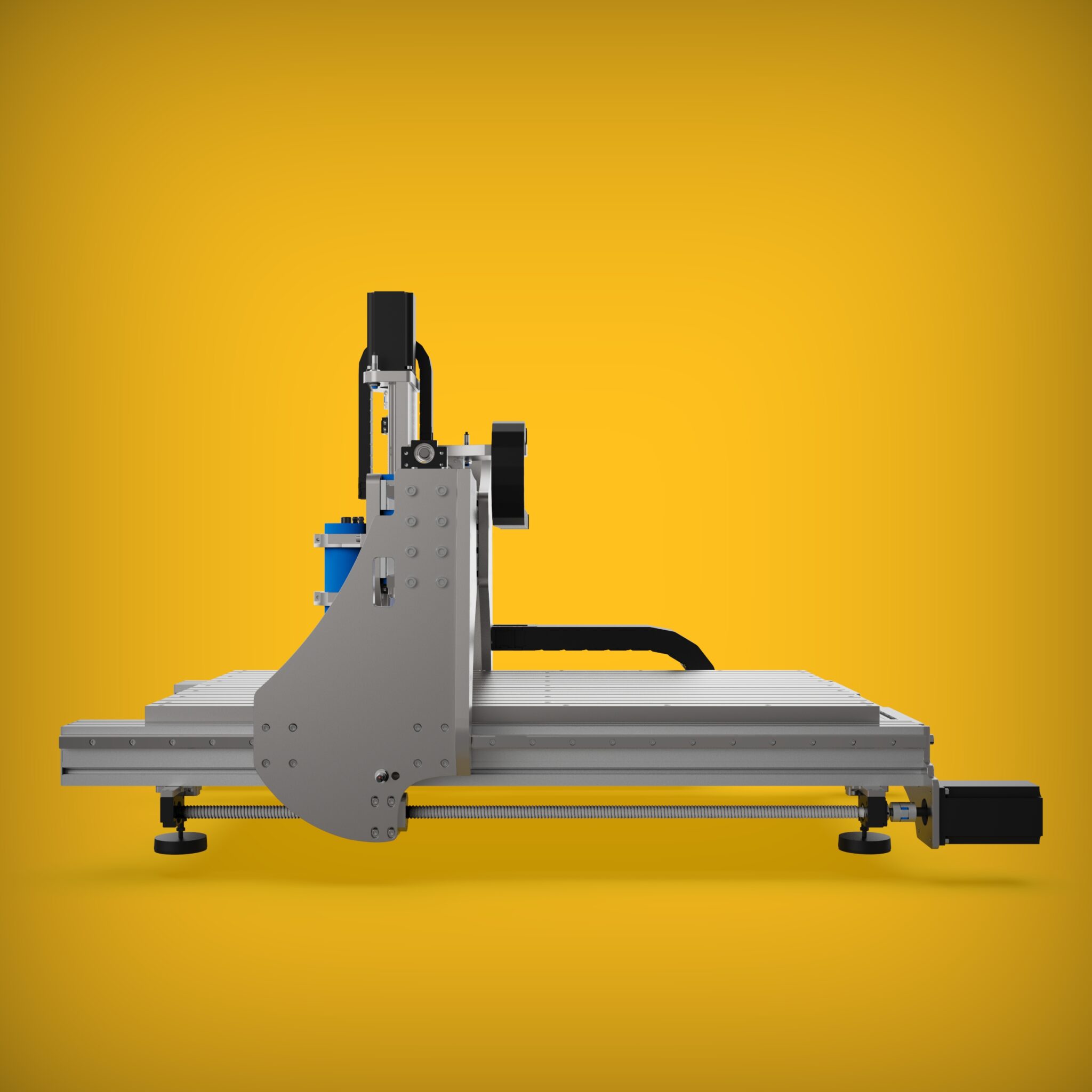

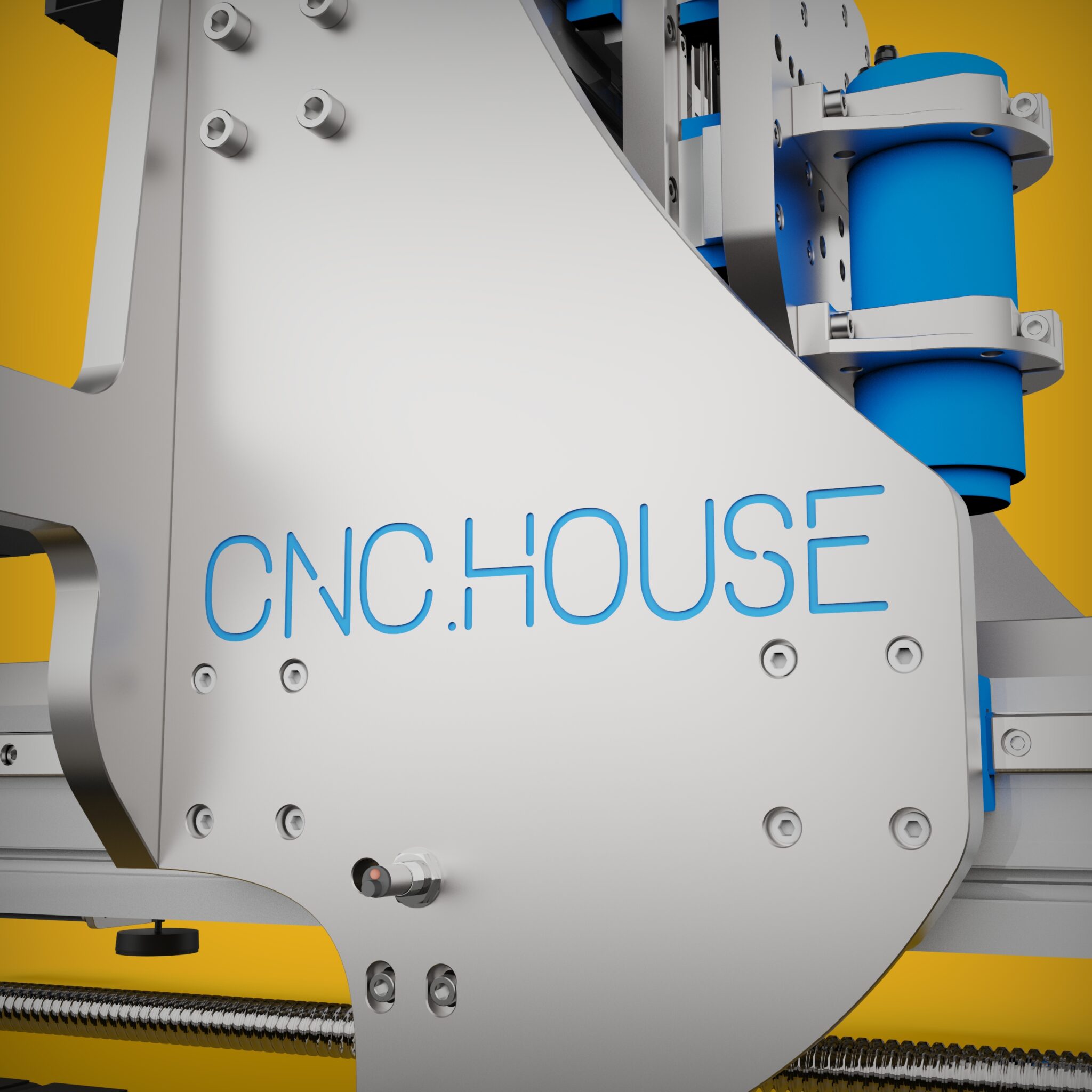

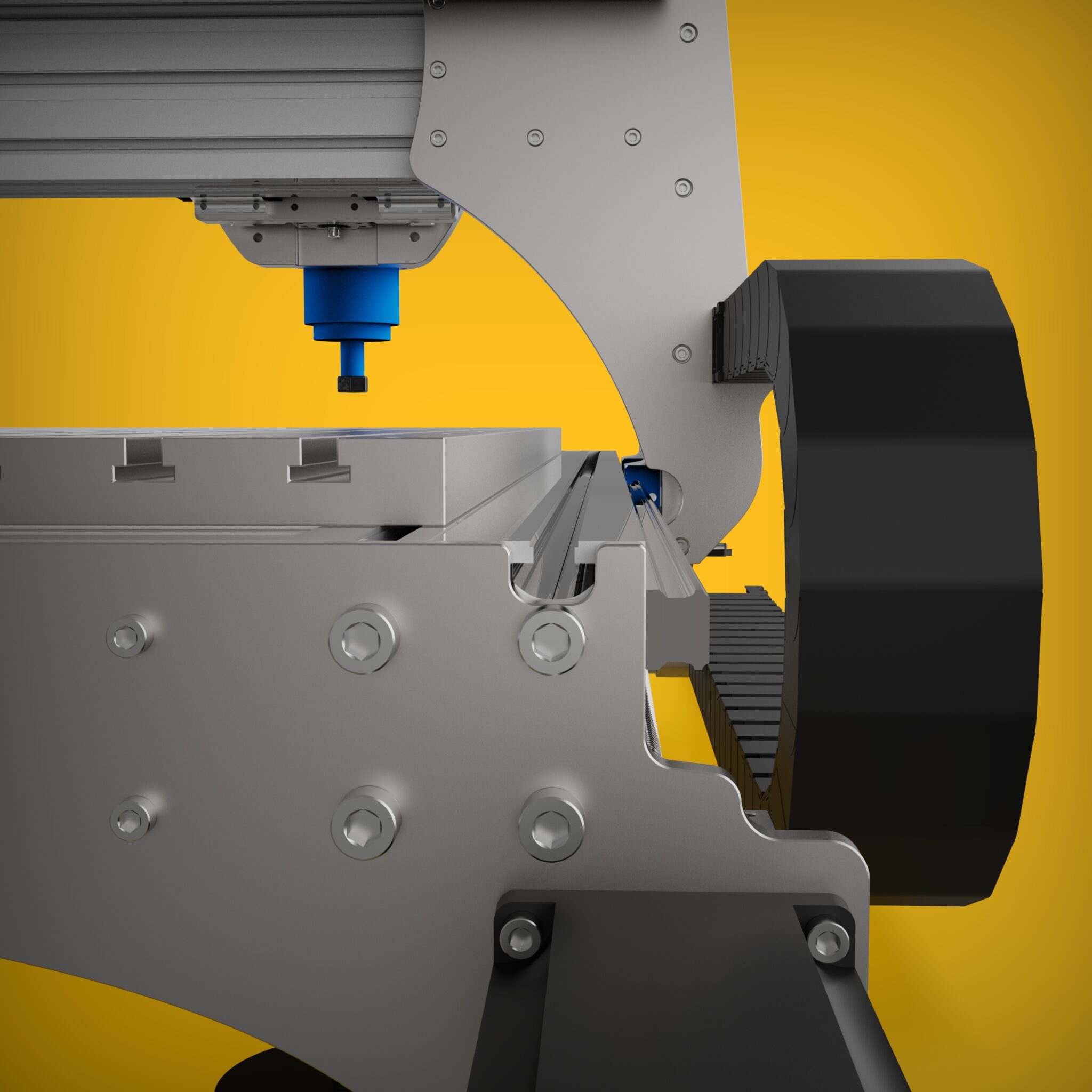

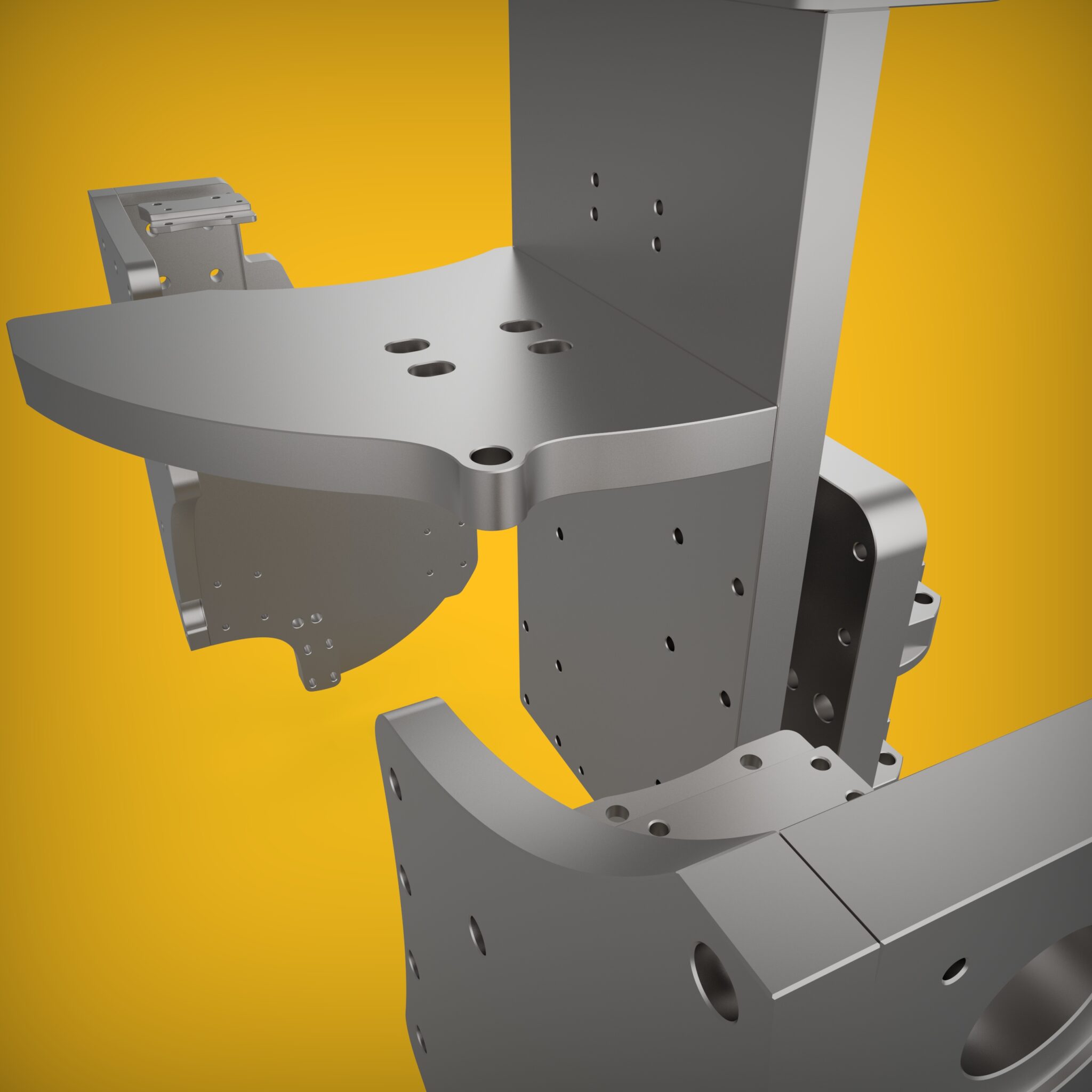

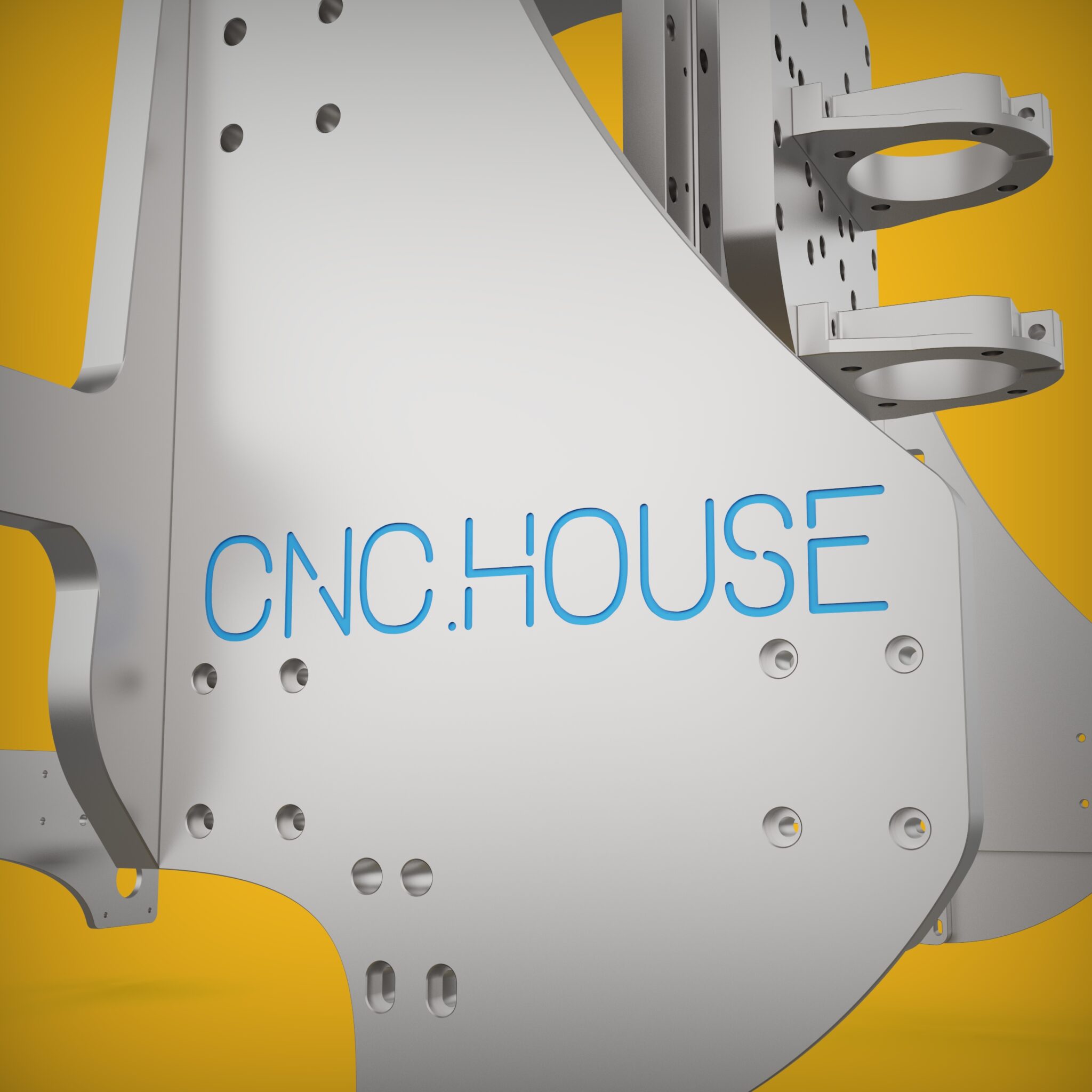

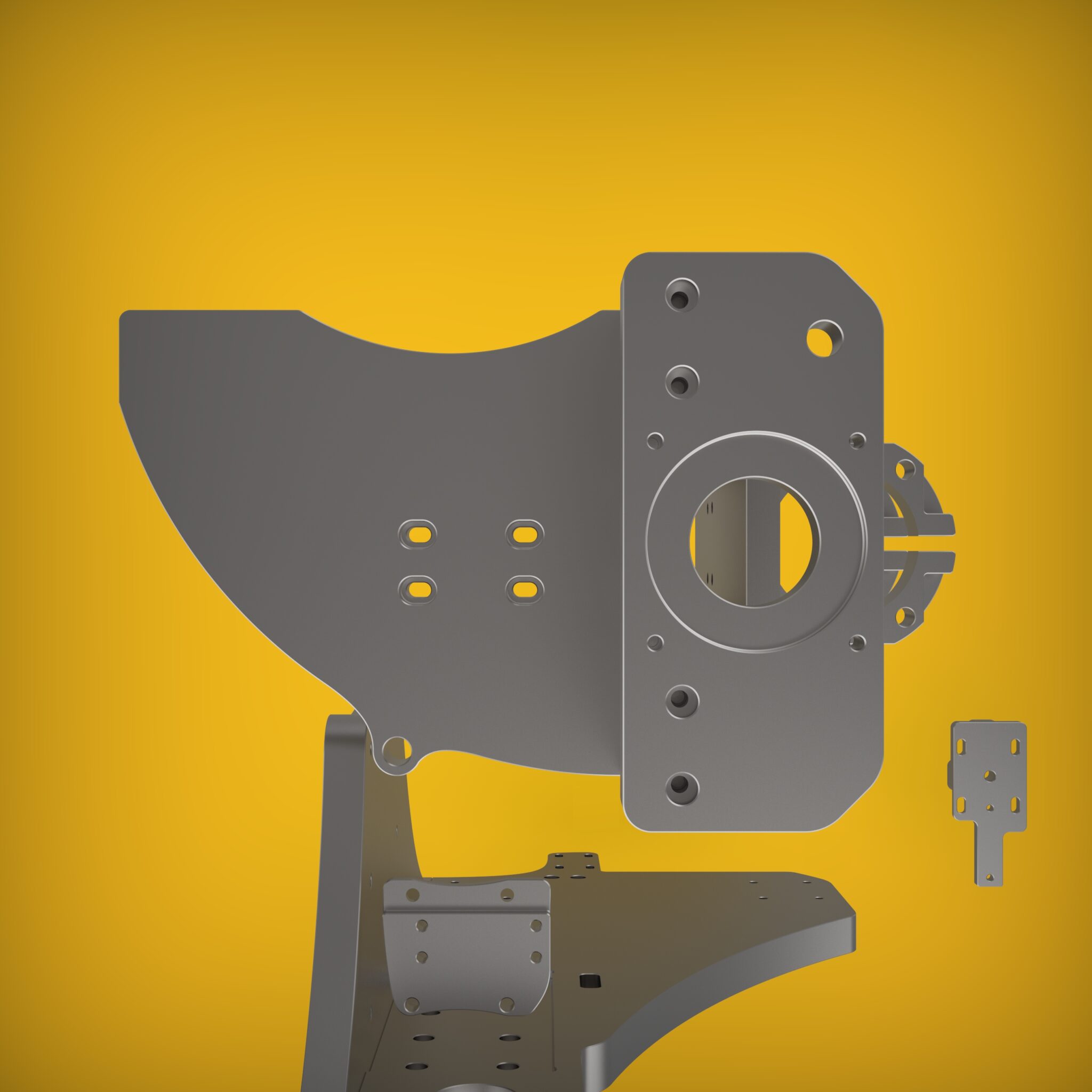

- Spindle Mount Holder: The model caters for an 80mm spindle mount holder, a common size for many milling applications, providing versatility and adaptability.

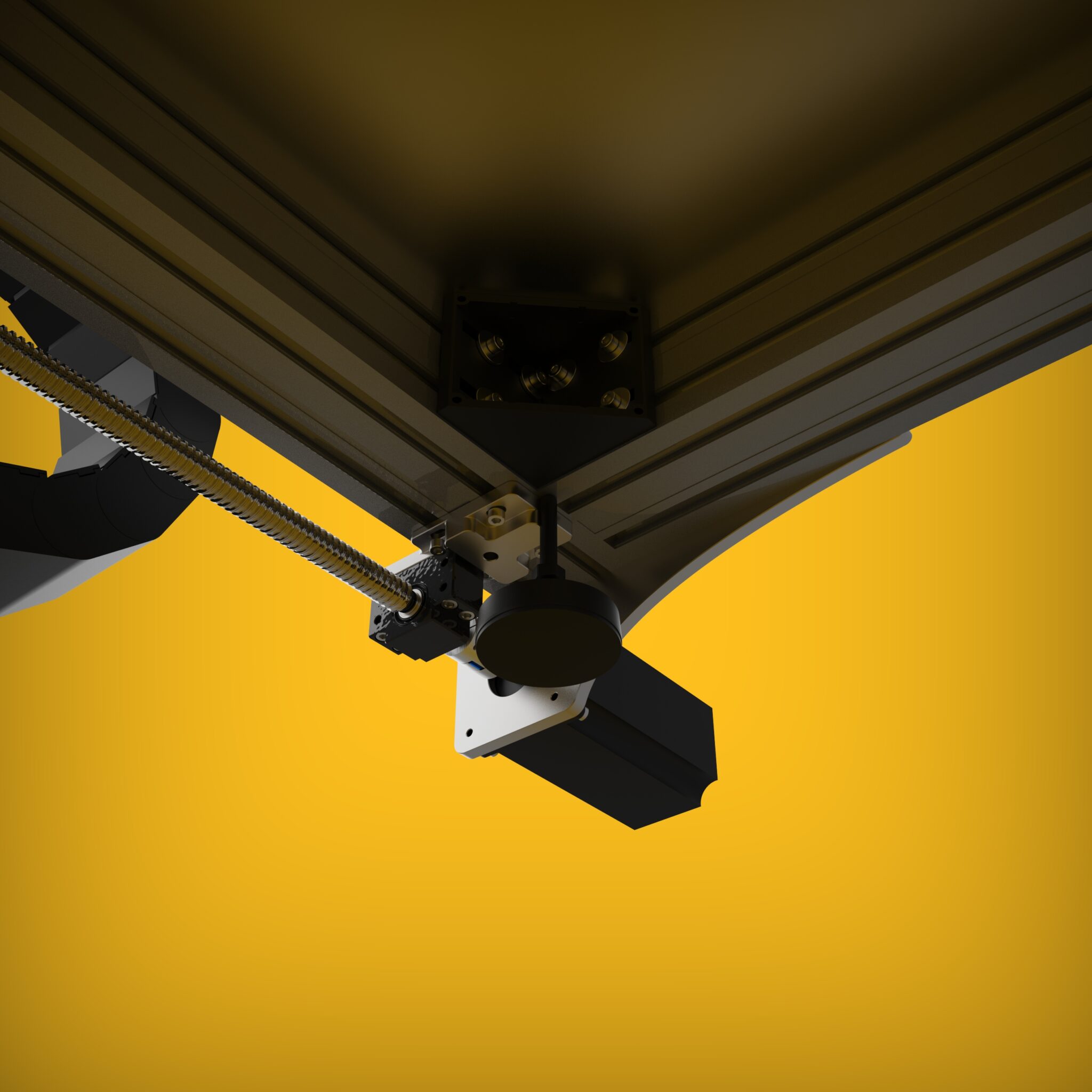

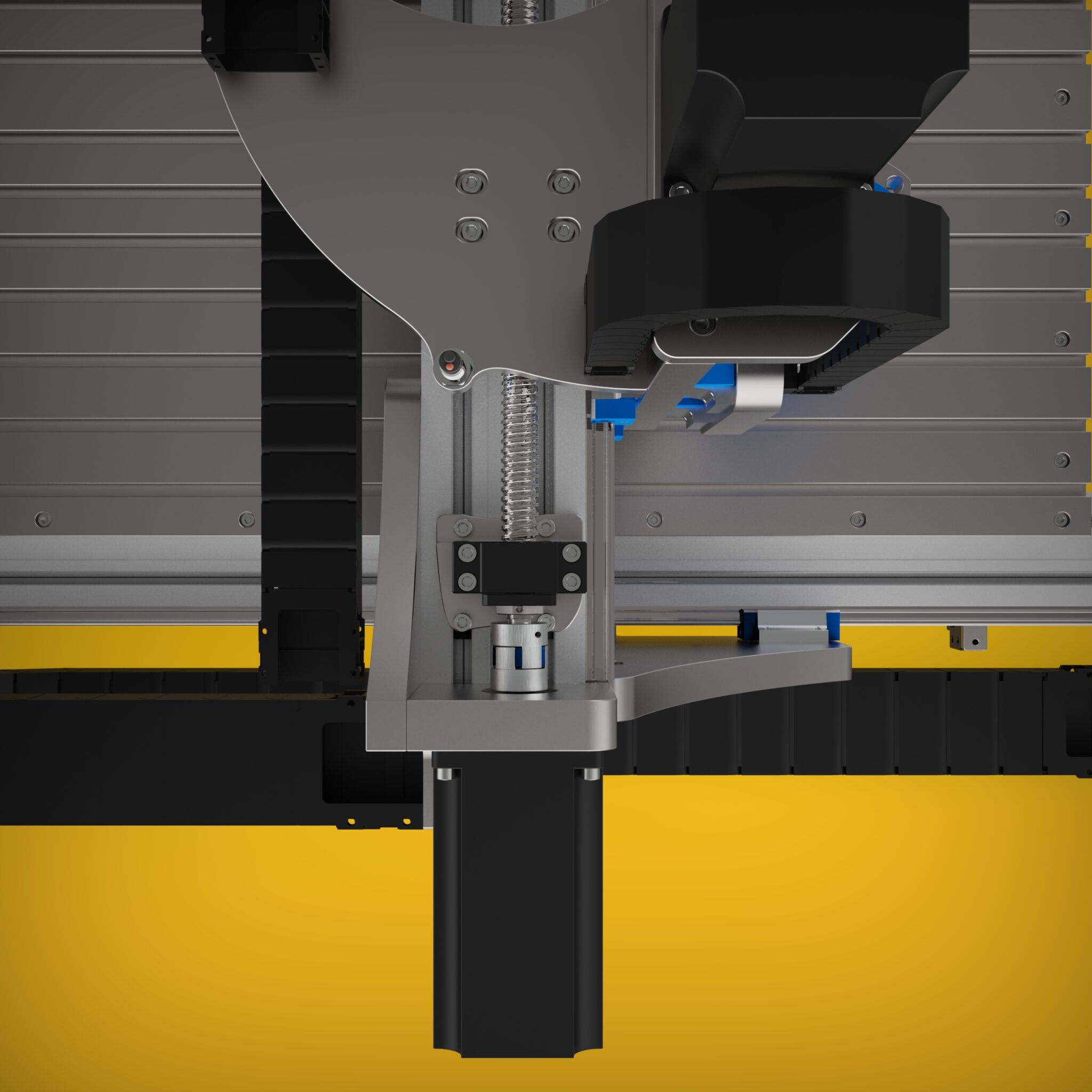

- Motor Type: This model is designed for Nema 34 type motors, offering high torque and precision for demanding machining tasks.

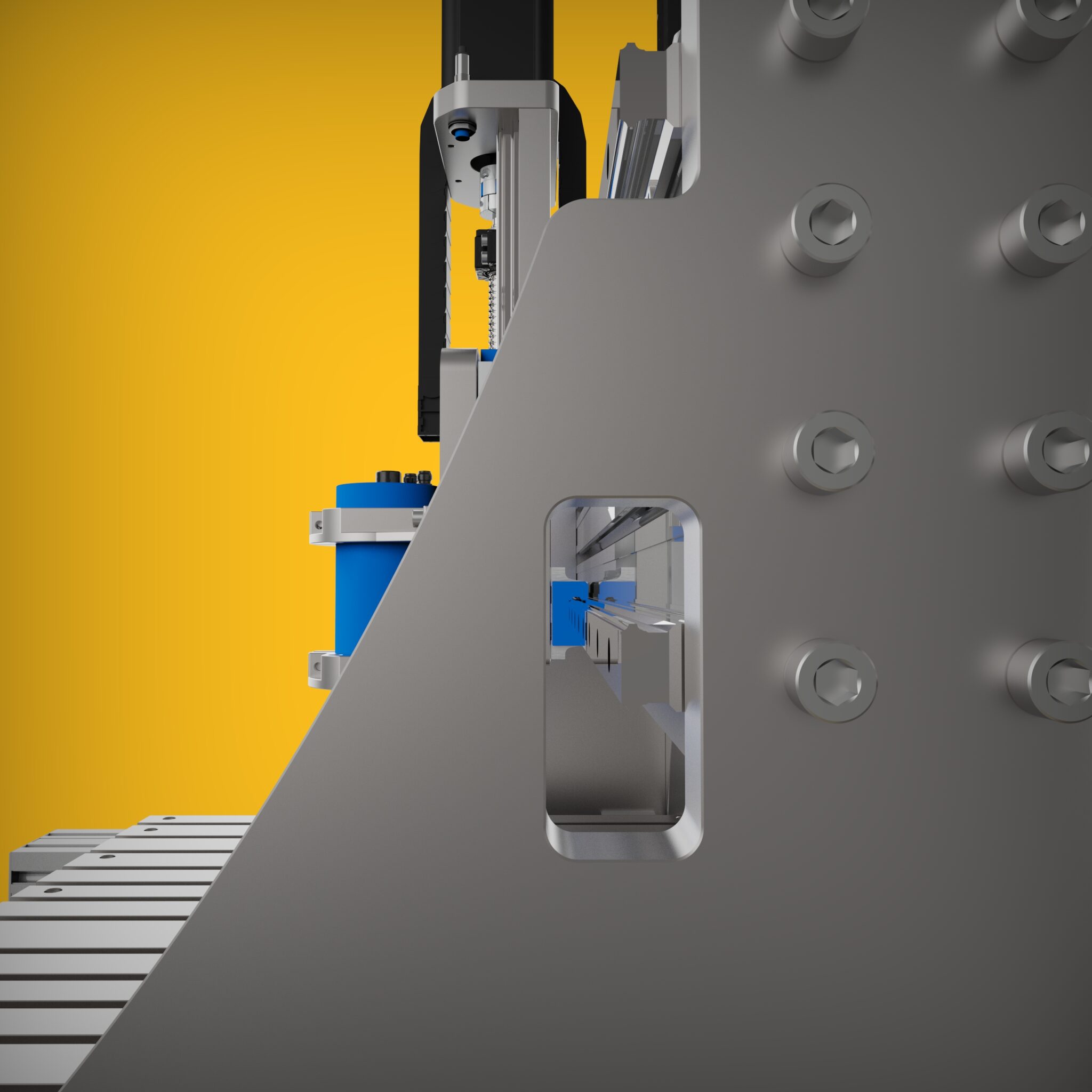

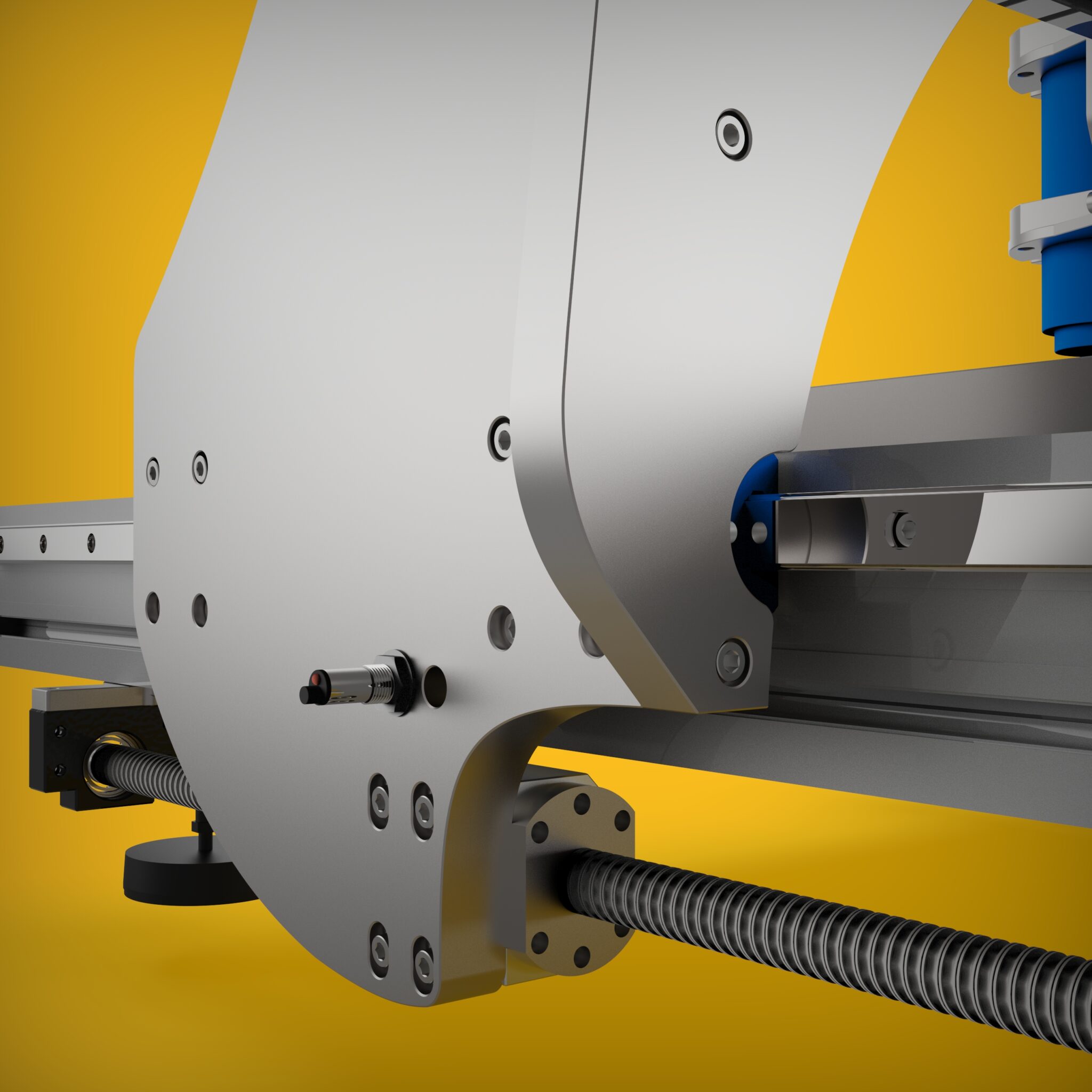

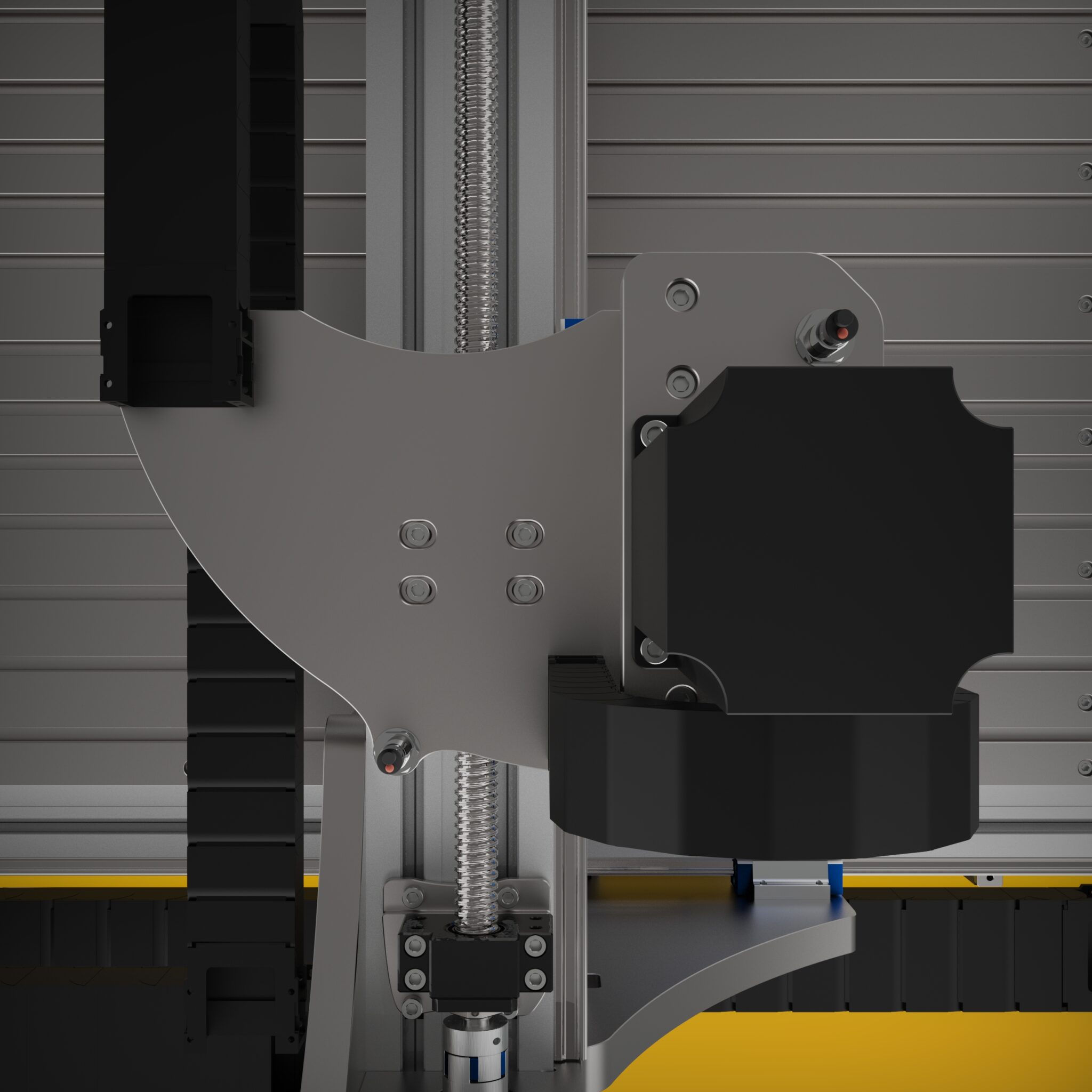

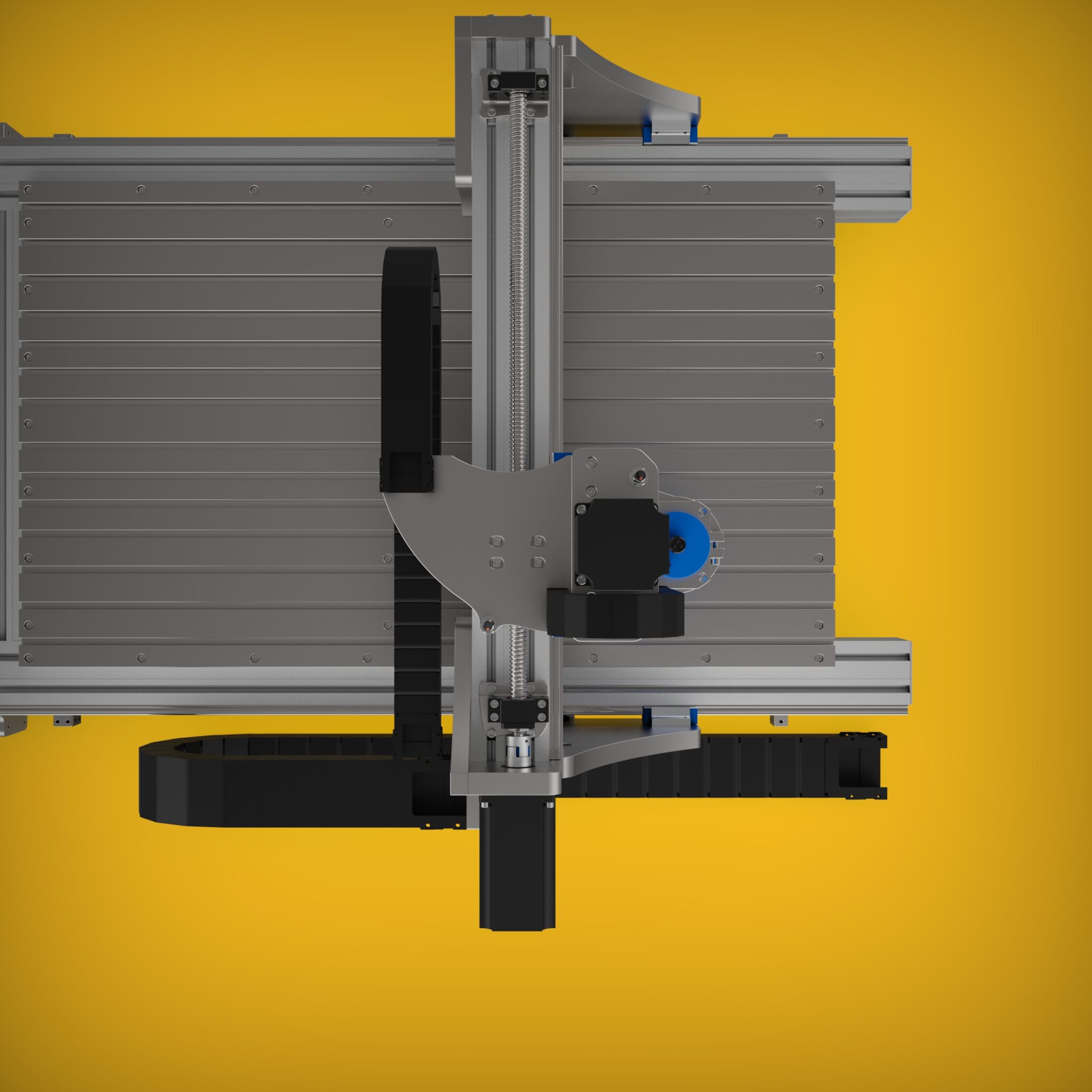

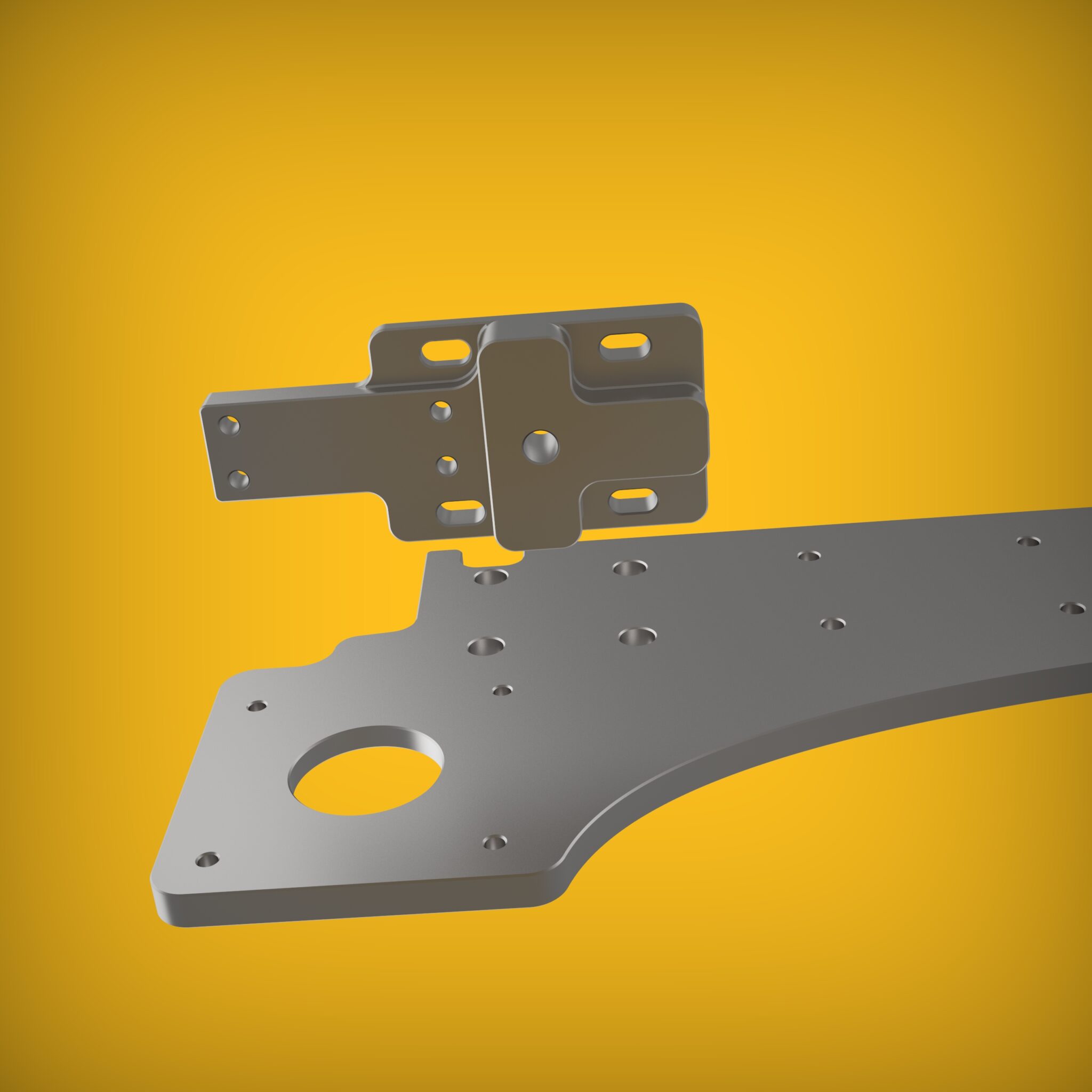

- Linear Blocks: The design incorporates TBI Motion TRH 20 FN or HIWIN HGW-20-CC linear blocks, well-known for their reliability and performance.

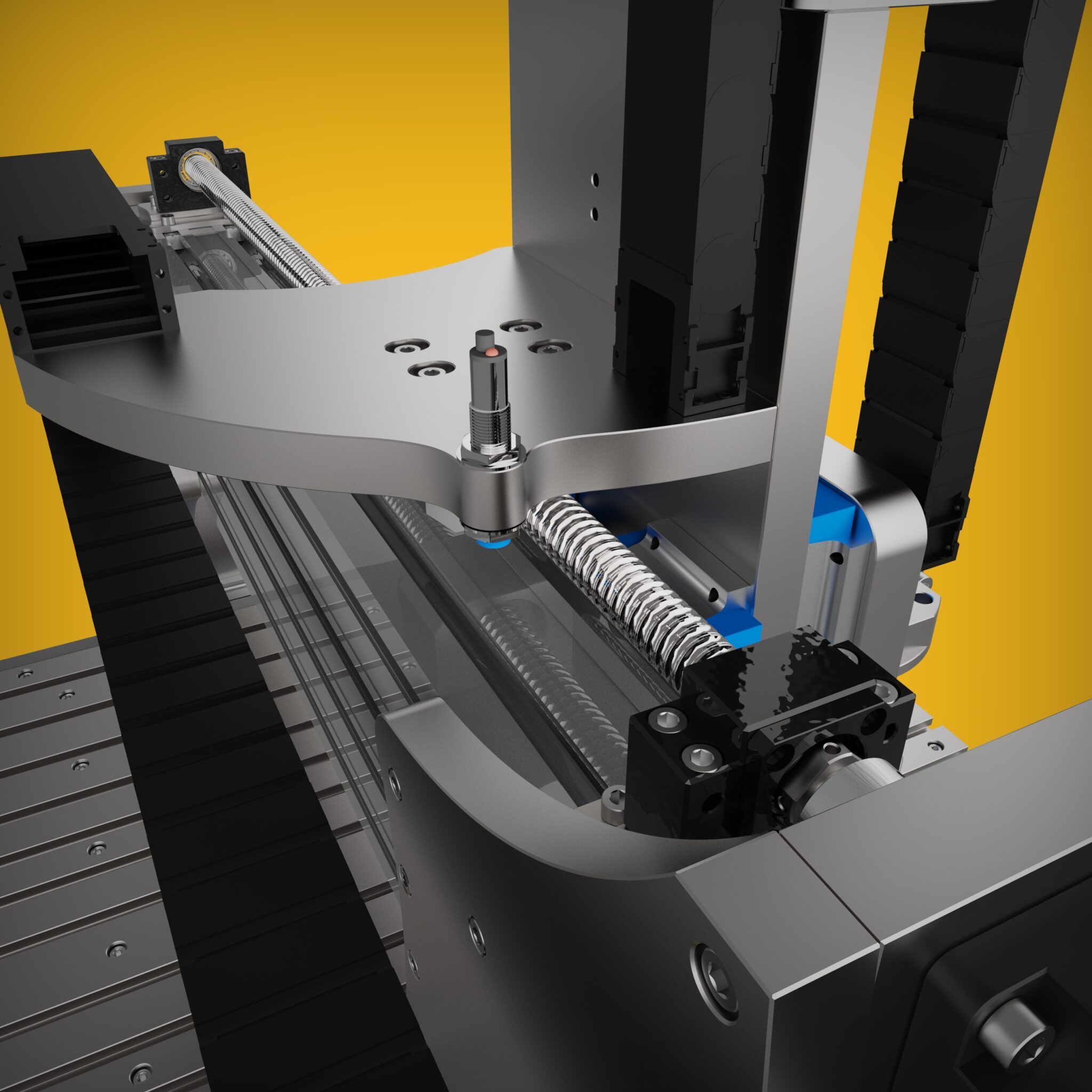

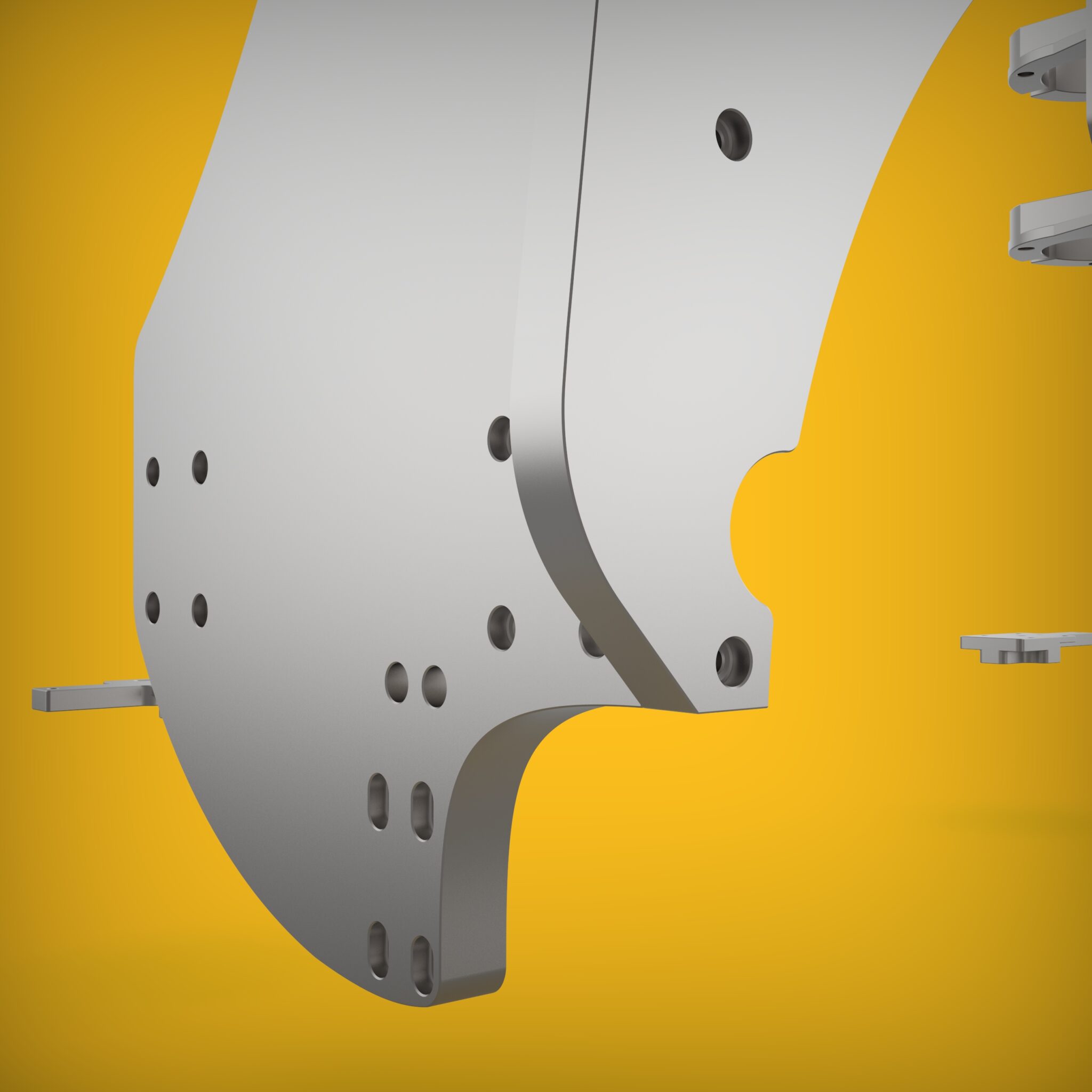

- Ball Screw Diameter: The model uses different types of ballscrews for each axis – Z Axis (Ballscrew 1605/1610), X Axis (Ballscrew 2005/2010), and Y Axis (2 x Ballscrew 2005/2010), ensuring precision and stability during operation.

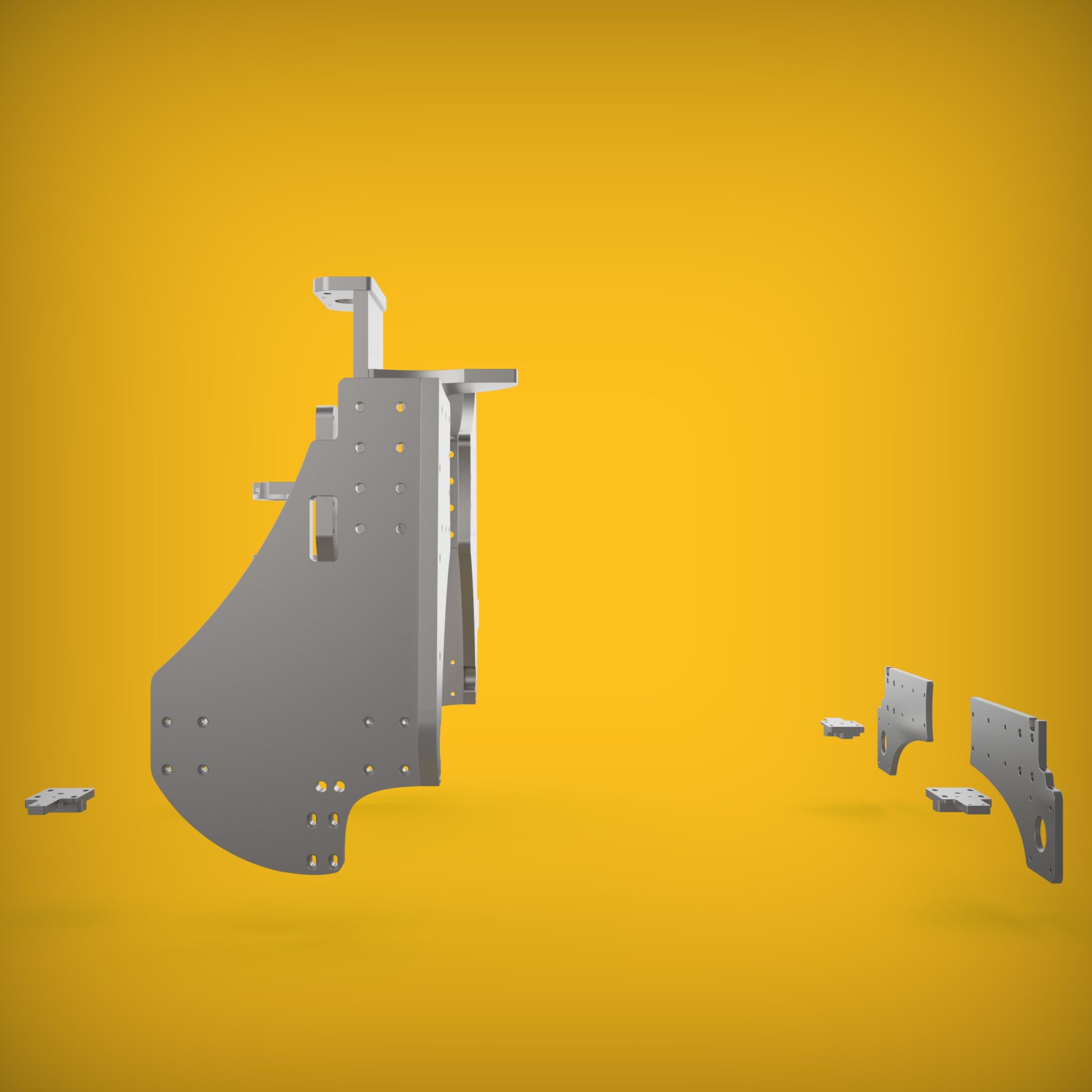

To complete the assembly of the CNC milling machine from this 3D model, you will need additional components.

These include:

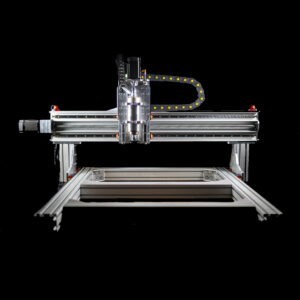

- Aluminium Profile 90×180 U10: This is for the portal beam. You can find it here.

- Aluminium Profile 90×90 U10: This is for the lower frame. You can find it here.

- Bracket ALU 90×90: Find it here.

- Leveling Feet FI80 M12: Find them here.

- Motor Type NEMA 34: You will need 4 stepper motors or a closed loop system or servo motor with a NEMA 34 86mm mount type.

- Ballscrews for Z, X and Y Axis: For Z axis, you need a Ballscrew SFU 1605 or 1610 with length 350mm + BF12 and BK12 supports. For the X axis, a Ballscrew SFU 2005 or 2010 with your length + BF15 and BK15 supports is necessary. For Y axis, 2 x Ballscrew SFU 2005 or 2010 with your length + 2 x BF15 and 2 x BK15 supports are required.

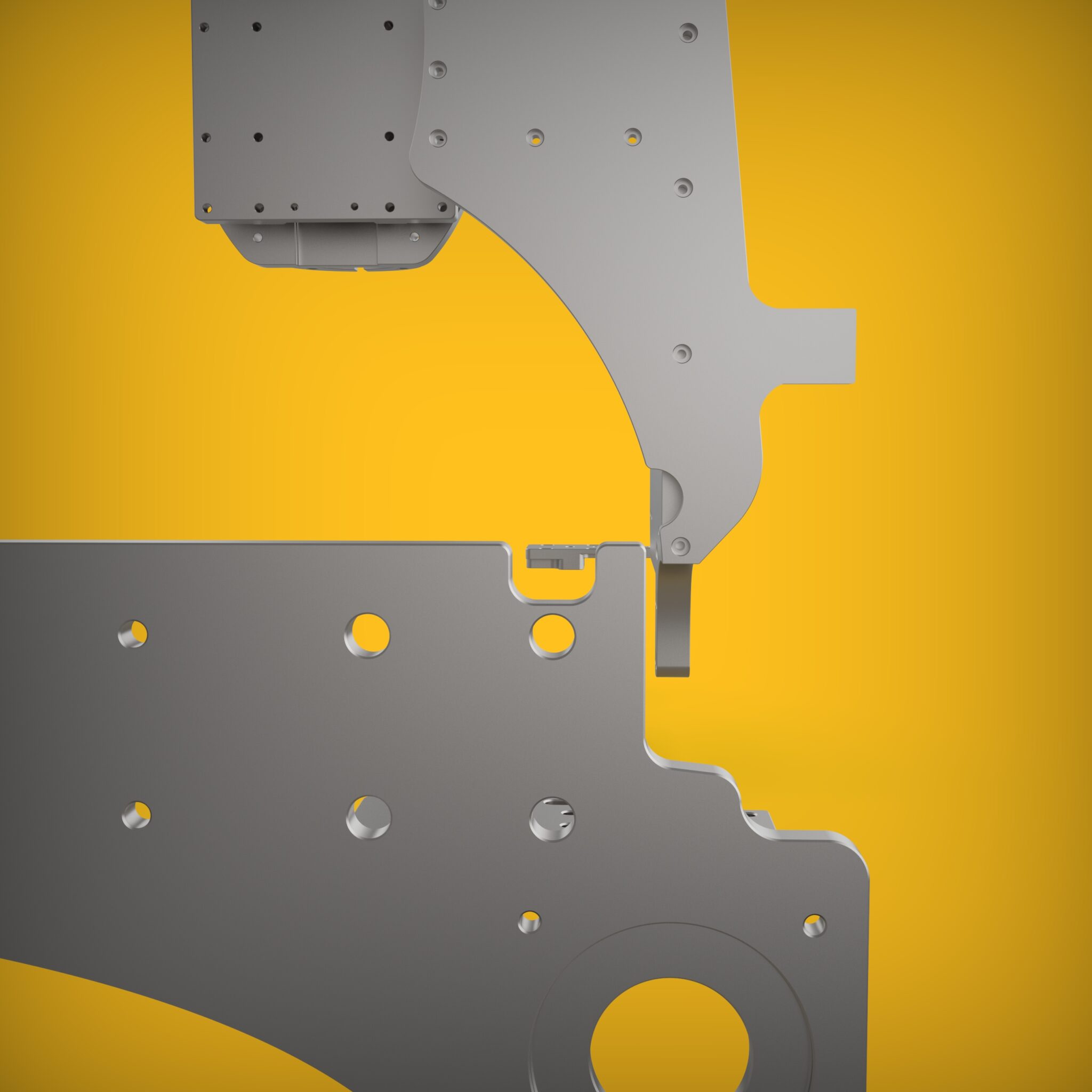

- Inductive Sensors: You need 4 inductive sensors with a M12 mount type (Z Axis – 1 x Home sensor, X Axis – 1 x Home sensor, Y Axis – 2 x Home sensors).

This 3D model serves as a comprehensive guide to build your own CNC milling machine, allowing you to bring industrial-grade precision and durability into your workshop. Please note that full assembly requires extra parts not included in the 3D model. Your journey towards creating exceptional milling results starts here.

Pro Line CNC Milling Machine 3D Model with Spurgear Racks: Unleashing the Power of Precision